P0700/P0710/P0850/P0860/P1000/P1010

4-4

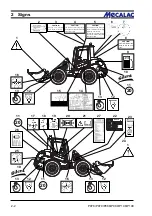

4

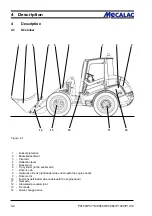

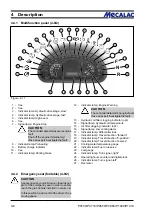

Description

Figure 4-3

Figure 4-5

Figure 4-4

Make sure the differential lock engages by releasing the

accelerator and steering movements if only one wheel of

an axle rotates with the differential lock enabled.

You may disable the differential lock while the loader is

moving.

CAUTION

Make sure to disable the differential lock when

driving on solid ground, in particular when taking

bends.

Service brake/ inching

AX 700/20 km/h and AX 850/20 km/h:

The loaders are equipped with a hydraulic drum brake in

the front axle acting on all four wheels.

AX 700/30 km/h, AX 850/30 km/h and AX 1000:

The loaders are equipped with a hydraulic disc brake in the

front axle acting on all four wheels.

The service brake is actuated with a pedal (4-3/arrow)

located to the left of the steering column. It is supported by

the hydrostatic traction drive (inching), i.e. during work,

the drive pedal is used for accelerating and braking.

Parking brake

The parking brake is actuated with a hand lever

(4-4/arrow) located to the left of the driver’s seat.

When actuated, the mechanic parking brake acting on all

four wheels switches off the traction drive.

Fuel supply system

The fuel tank is located on the left-hand side of the loader

rear. An electrical fuel gauge (4-11/23) in the operator’s

cabin monitors the fuel level in the tank. The filler neck

(4-5/arrow) is located beneath the engine hood on the left

loader side.

Air filter device

Dry air filter system with safety cartridge (opt.) and

umbrella valve.

Lift and tip devices

Via a servo valve a double-acting gear-type pump drives

- two lifting cylinders

- one tip cylinder

All movements of the bucket arm, the bucket, the attach-

ments and the quick-change device are controlled from the

driver’s seat by pilot valves.

These pilot valves provide continuous speed control from

“slow” to “fast”.

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...