P070/P071/P085/P086/P100/P101

5-3

Operation

5

Figure 5-2

5.2.2

Winter operation

CAUTION

If the outside temperature is below 0 °C, the

machine must be properly „warmed up“ to avoid

damage to certain assemblies. To do so, actuate

all cylinders (lifting and tipping cylinders) for

some time (depending on the ambient tempera-

ture) with the machine idling.

Proper operation of the machine, even for sub-

zero temperatures, can only be guaranteed if the

following measures have been taken:

5.2.2.1 Fuel

At low temperatures, paraffin precipitating from the fuel

can cause the fuel system to clog up.

For this reason, always use winter diesel fuel (suitable for

temperatures down to -15 °C) when the outside tempera-

ture is below 0 °C.

NOTE

The fuelling stations normally start offering winter

diesel fuel in good time before the cold season

starts. Often, they offer diesel fuel that can be

used down to temperatures of -20 °C (super-

grade diesel fuel).

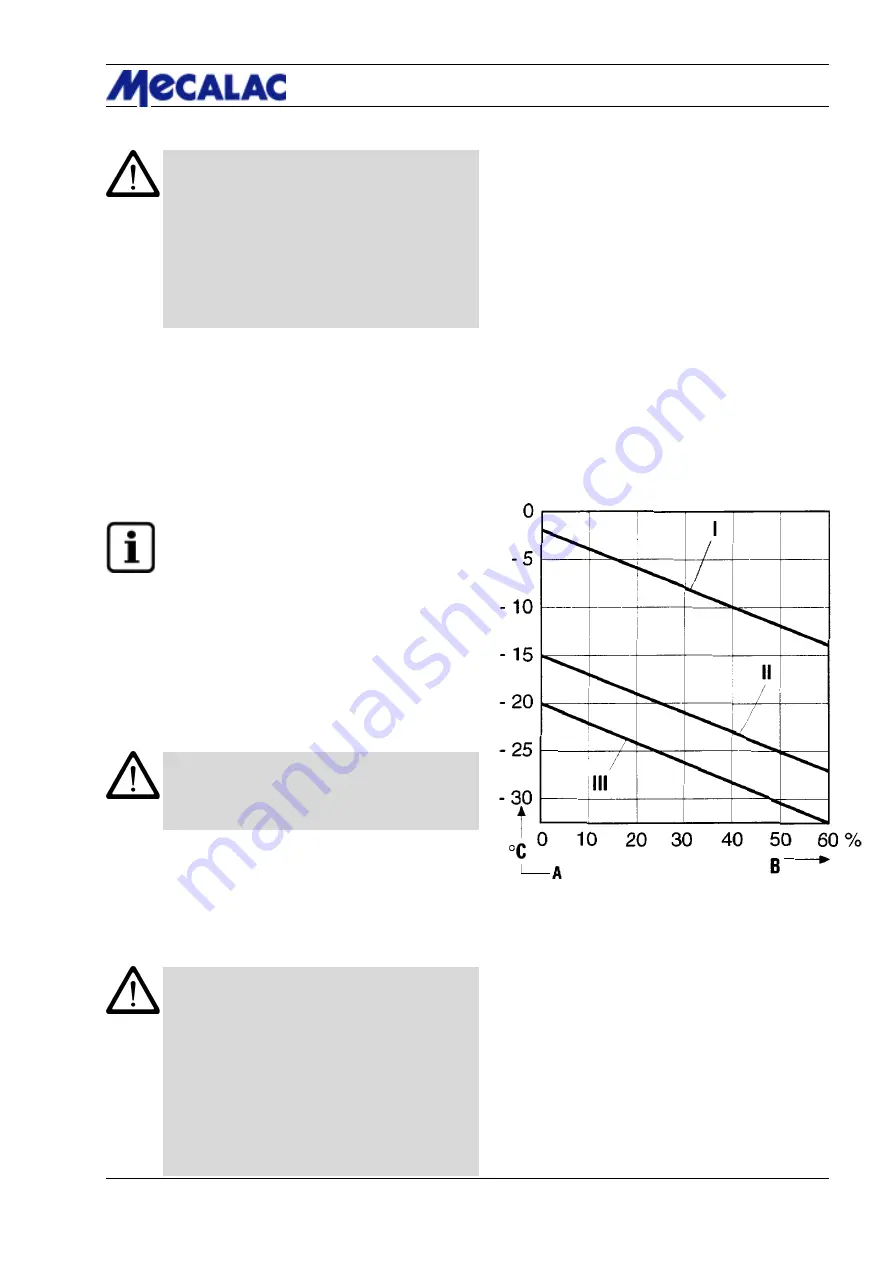

If the temperature is below -15 °C or -20 °C,

paraffin oil must be added to the diesel fuel. For

the mixture ratio, refer to the diagram (5-2).

I

= Summer diesel fuel

II = Winter diesel fuel

III = Super-grade diesel fuel

CAUTION

Only mix the ingredients in the tank! First, fill in the

required amount of paraffin oil, then top up with

diesel fuel.

5.2.2.2 Engine oil change

See the operating instructions for the engine.

5.2.2.3 Hydraulic system oil change

CAUTION

The viscosity of the hydraulic oil changes accor-

ding to the temperature; therefore, the ambient

temperature in the place where the machine will

be used determines what viscosity class (SAE

class) must be chosen. If the hydraulic oil used

matches the expected ambient temperature,

optimum operating conditions can be attained.

Therefore, use hydraulic oil of an appropriate

grade if required.

See section 8.2.11 for the hydraulic system oil

change.

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...