P070/P071/P085/P086/P100/P101

7-6

7

Rescue, towing,

lashing, lifting by crane

D

A

2

C

2

D

B

A

1

C

1

1

2

1

2

NOTE

After towing has been completed, loosen the

hexagon nuts again. Screw the setscrews out of

both high-pressure relief valves until they stop

and tighten the lock nuts.

(12) Remove the chocks (if applicable).

(13) Release the parking brake (4-9/3).

DANGER

- With the engine running, tow the loader at

walking speed (2 km/h).

- The towing distance should not exceed 1 km.

- For a longer distance, the defective loader must

be loaded onto a truck (for the lashing points,

see 7-2/arrow, 7-7/6/arrows and 7-7/arrows).

- The max. permissible load of the shunting and

towing coupling (7-2/2) is 4.5 t horizontally in

the longitudinal direction.

- The max. permissible load of the lashing/load-

bearing points (7-6/arrows, and 7-7/arrows) is

2.0 t.

7.2

Lifting by crane

The loader to be lifted must be prepared as follows:

(1) Set the drive switch (4-10/11) to “0”.

(2) Set hydraulic drive stage „I“ (4-10/9).

(3) Apply the parking brake (4-9/3).

(4) Lift or lower the bucket arm until the lowest point of the bucket

arm or of the bucket is at least 30 cm above the road (5-4).

(5) Close the pilot valve for the working and auxiliary

hydraulics (1-2/arrow).

(6) Insert the articulation safeguard into the articulation

joint (1-3/arrow).

CAUTION

Do not operate the steering while the articulation

safeguard is in place.

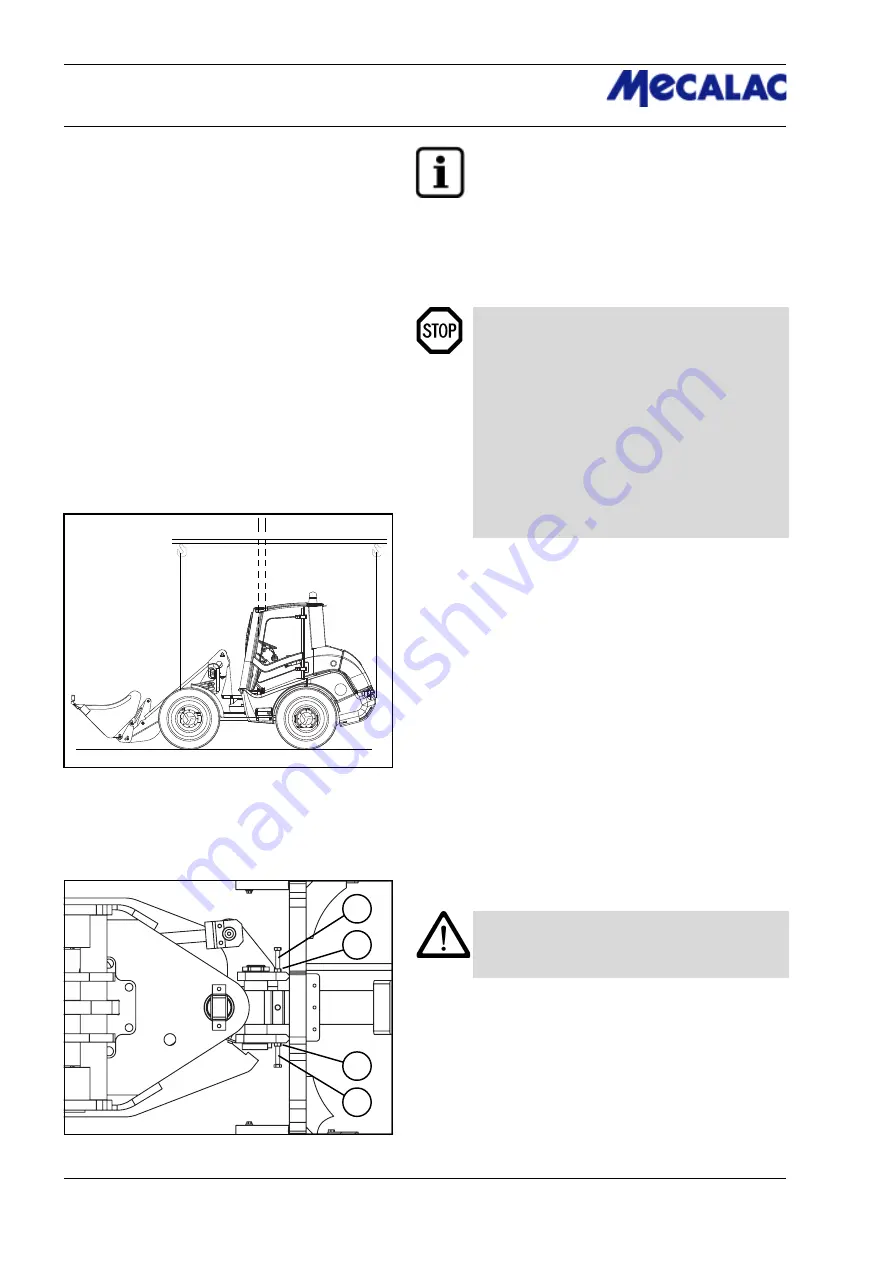

(7) Engage the float safeguard. To do so, loosen lock nuts

(7-9/1) on the left and right of the loader, screw in securing

screws (7-9/2) all the way to the stop and tighten lock nuts

again.

(8) Lock both doors.

(9) Fold the outside mirror inwards.

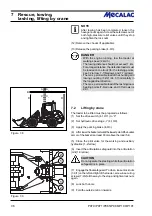

Figure 7-8

Figure 7-9

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...