P0700/P0710/P0850/P0860/P1000/P1010

8-4

8

Maintenance

Figure 8-3

Figure 8-2

8.2

Maintenance work

8.2.1

Oil level check, engine

See the operating instructions for the engine.

8.2.2

Oil change, engine

See the operating instructions for the engine.

8.2.3

Maintaining/replacing the air filter

NOTE

- Maintenance (visual inspection) of the filter

cartridge must be carried out every

10 ope-

rating hours

. According to the operating con-

ditions, shorter intervals may apply.

- Clean the filter cartridge if necessary.

- Replace the filter cartridge every

500 ope-

rating hours

.

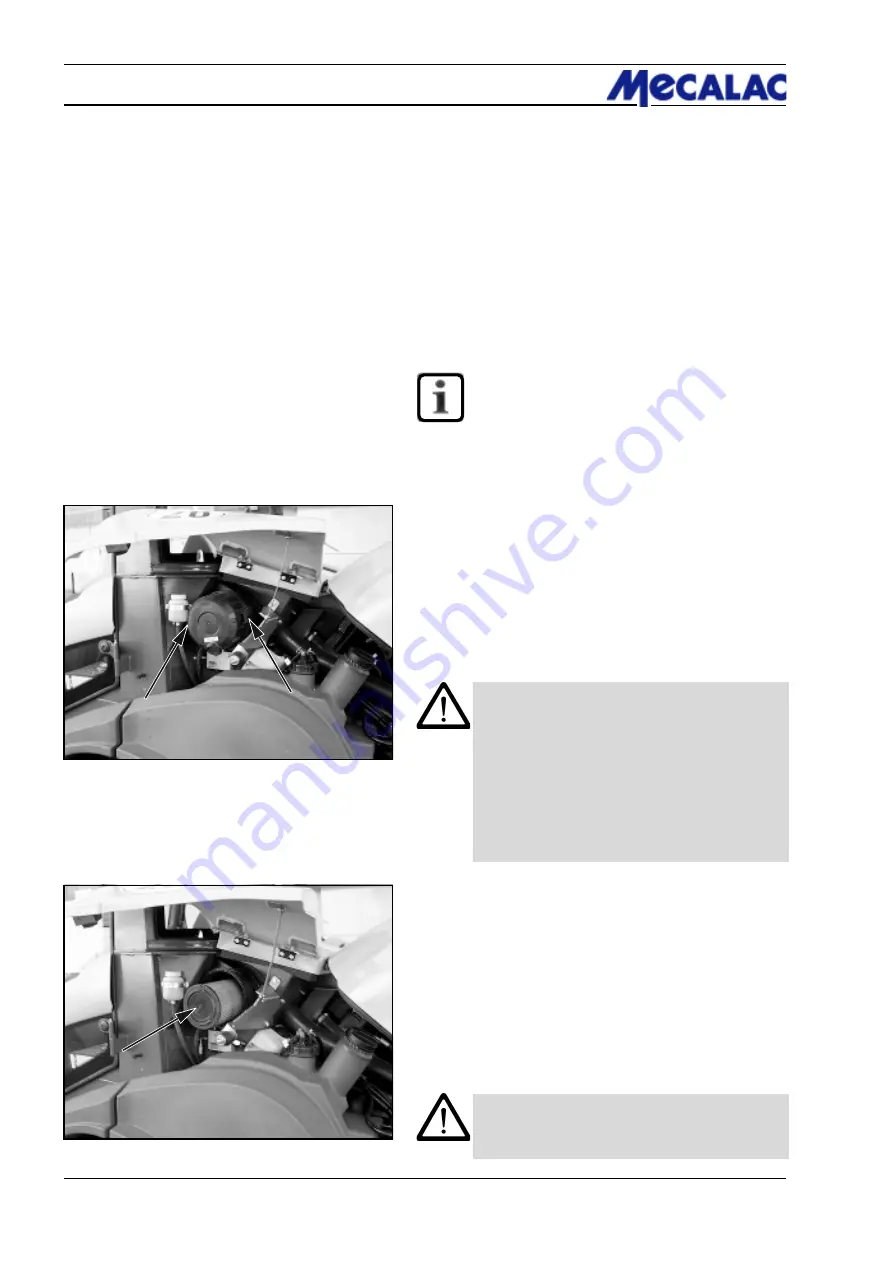

(1) Open the engine hood, then the maintenance flap on

the loader’s left side.

(2) Loosen the three retaining clamps of the air filter lid

(8-2/arrows) and remove the air filter lid.

(3) Pull out the filter cartridge (8-3/arrow) by carefully

turning it back and forth.

(4) Clean the filter cartridge.

CAUTION

- For cleaning, use a compressed air gun to

which a pipe (angled at 90°) has been attached.

The pipe must be sufficiently long to reach the

bottom of the cartridge. Use dry compressed

air of no more than 5 bar to blow out the

cartridge by moving the pipe back and forth in

the interior of the cartridge. Cleaning can be

stopped when dust formation ceases.

- Do not use petrol or hot liquids for cleaning.

(5) Use a hand-held lamp to check the cartridge paper

and the rubber gasket of the filter cartridge for damage.

If the cartridge or the gasket is damaged, replace the

cartridge.

(6) Carefully insert the filter cartridge.

(7) Install the air filter lid on the filter housing in such a way

that the direction arrow in the marking "

OBEN-TOP

“ points

upwards. This ensures that the umbrella valve faces

downwards.

CAUTION

Check all connection pipes and hoses of the air filter

system for damage before starting the engine.

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...