P0700/P0710/P0850/P0860/P1000/P1010

8-15

Maintenance

8

1

3

2

Figure 8-36

Figure 8-34

Figure 8-35

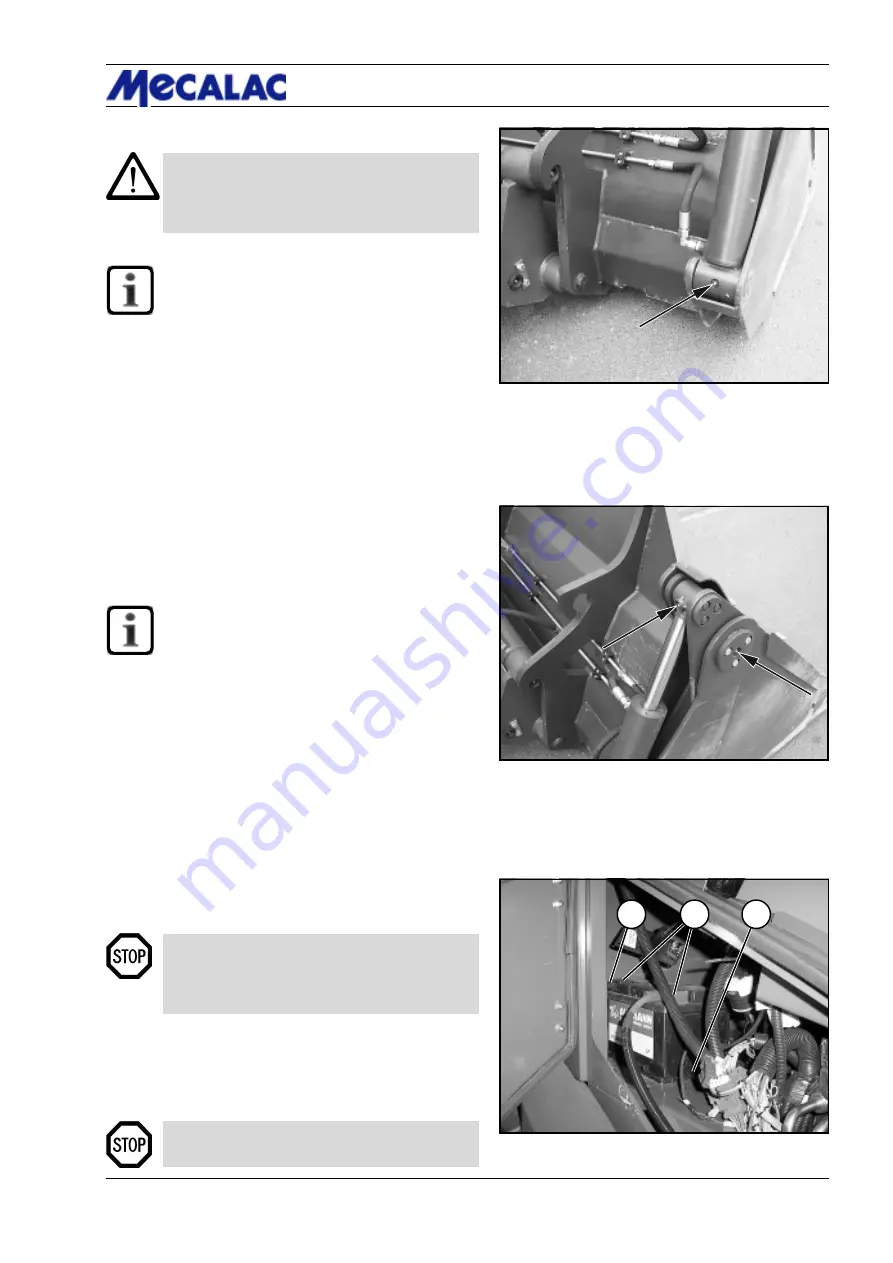

8.2.13.5

Multi-purpose bucket

CAUTION

The bearing bolts of the multi-purpose bucket

(8-35/arrows) must be greased

every 10 ope-

rating hours.

NOTE

The bolts must be greased on both sides of the

multi-purpose bucket.

8.2.14 Oil lubrication points

Lubricate the following items with oil every 50 operating

hours:

- The door locks,

- the Bowden cable and leverage of the accelerator

pedal.

8.2.15 Replacing the starter battery

NOTE

The starter battery is a maintenance-free part

according to DIN 72311, section 7. It is located

behind the maintenance flap at the loader right.

(1) Opening the window: First pull the window handle

inwards, then push it outwards. Finally lift the window

handle out of its holder.

(2) Open the maintenance flap with a square wrench.

(3) Unlock the battery main switch (opt.) (8-36/1) by

giving it 2 counter clockwise turns.

(4) Loosen and remove the fastening screw (8-36/3)

(size 17) of the battery holder.

(5) Swing up the cover of the front terminal loosen and

disconnect terminals (8-36/2) from the battery (size 13).

DANGER

Always remove the negative terminal first and

then the positive terminal. Installation is in reverse

order.

(6) Remove the battery and replace it.

(7) Apply grease to the terminals before fastening them.

(8) Installation is in reverse order.

DANGER

Make sure the fastenings are secure.

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...