NEED HELP? 1-800-832-2966

21

MAINTENANCE/CARE

Proper routine maintenance of this machine is essential for safe, economical, and trouble-free operation. It will help prolong the life of this machine

as well as help reduce air pollution. Perform maintenance checks and procedures according to the schedule below. It is recommended to use

genuine Mech Marvels parts for any replacement needs. Use of non-Mech Marvels parts can damage or reduce the life of your machine. Before

performing any maintenance, turn engine off and remove the wire from the spark plug to prevent accidental starting and serious injury. If you have

questions about maintenance procedures described in this manual, call 1-800-832-2966 Monday - Friday, 9 AM - 6 PM Central Time.

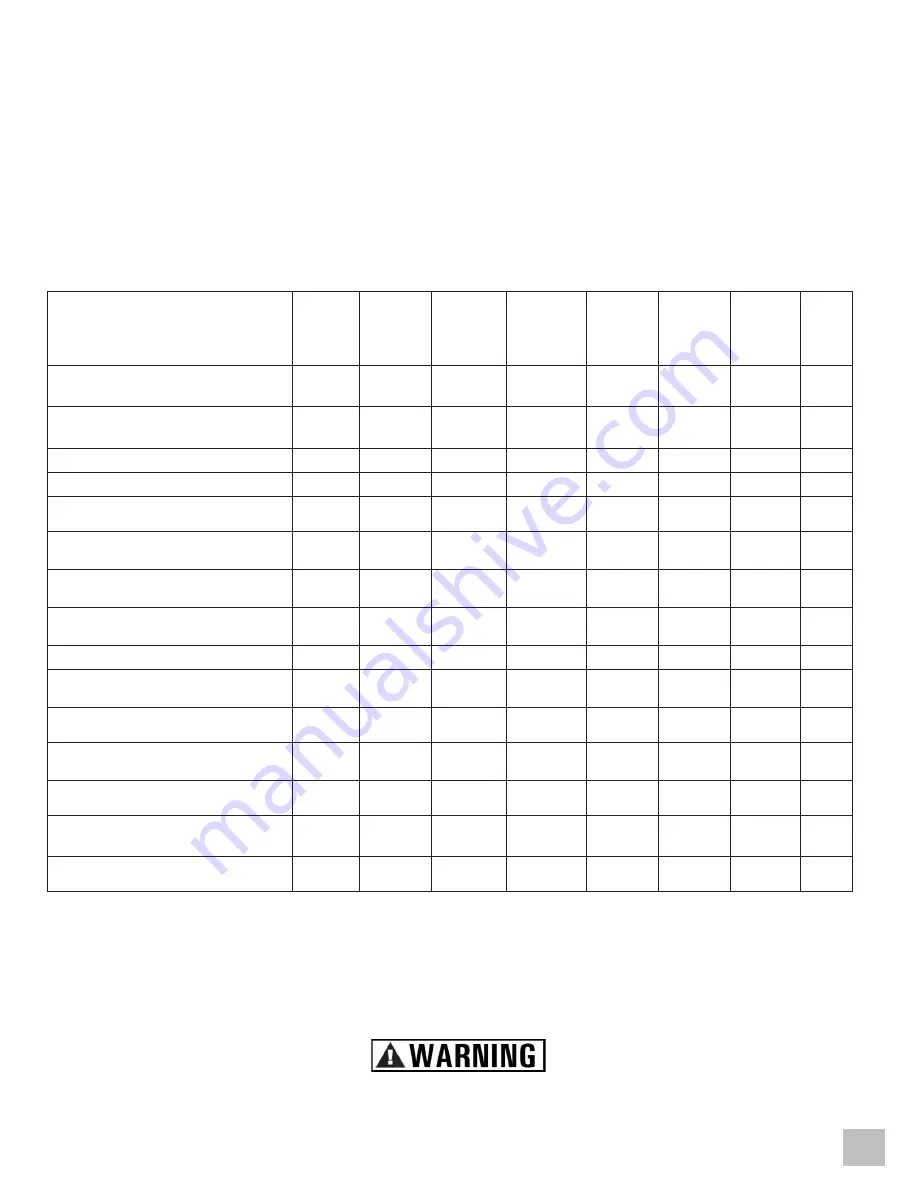

Recommended Maintenance Schedule

Service Records-

Fill in dates as you complete regular

service

Before

Each Use

After

Every

10 Hours

of Use

After

Every

25 Hours

of Use

After Every

50 Hours of

Use

After

Every

100 Hour

of Use

Before

Each

Season

Before

Storage

See

Note

Below

Check air pressure in tires.

√

Check Engine Oil Level,

Fill to Proper Level

√

√

Clean Debris from Unit

√

√

√

Lubricate All Pivot Points

√

√

√

Check Fasteners for Tightness

√

√

1

Check Drive Belts

Replace if Necessary

√

√

Check Tines for Wear or Damage

Replace if Necessary

√

√

Check Fuel Line

Replace if Necessary

√

√

Lubricate Wheel Axles

√

√

√

Check Spark Plug

Replace if Necessary

√

√

Change Engine Oil

√

√

√

2,3

Clean Air Filter

Replace if Necessary

√

√

√

4

Replace Spark Plug

√

Clean Combustion Deposits from

Cylinder, Piston, and Valves

√

Check Transmission Lubrication

√

√

Important notes about the maintenance schedule:

1. Re-check tightness of all fasteners after first 2 hours of initial use.

2. Change engine oil after first 5-8 hours of initial use.

3. Change oil every 25 hours if operating under heavy load or in high temperatures.

4. Clean air filter every 10 hours if operating under dusty conditions.

Use only GENUINE Mech Marvels replacement parts. Other parts may damage the unit and could result in injury.