14

Mecmesin

Vortex-dV Operating Manual

Half Cycle

A half-cycle test is to an angular displacement relative to tared zero.

Movement always ends at the angle set in the starting direction, shown in red below.

A half-cycle only starts when the drive spindle is at the furthest displacement position,

relative to tared zero, from the end position.

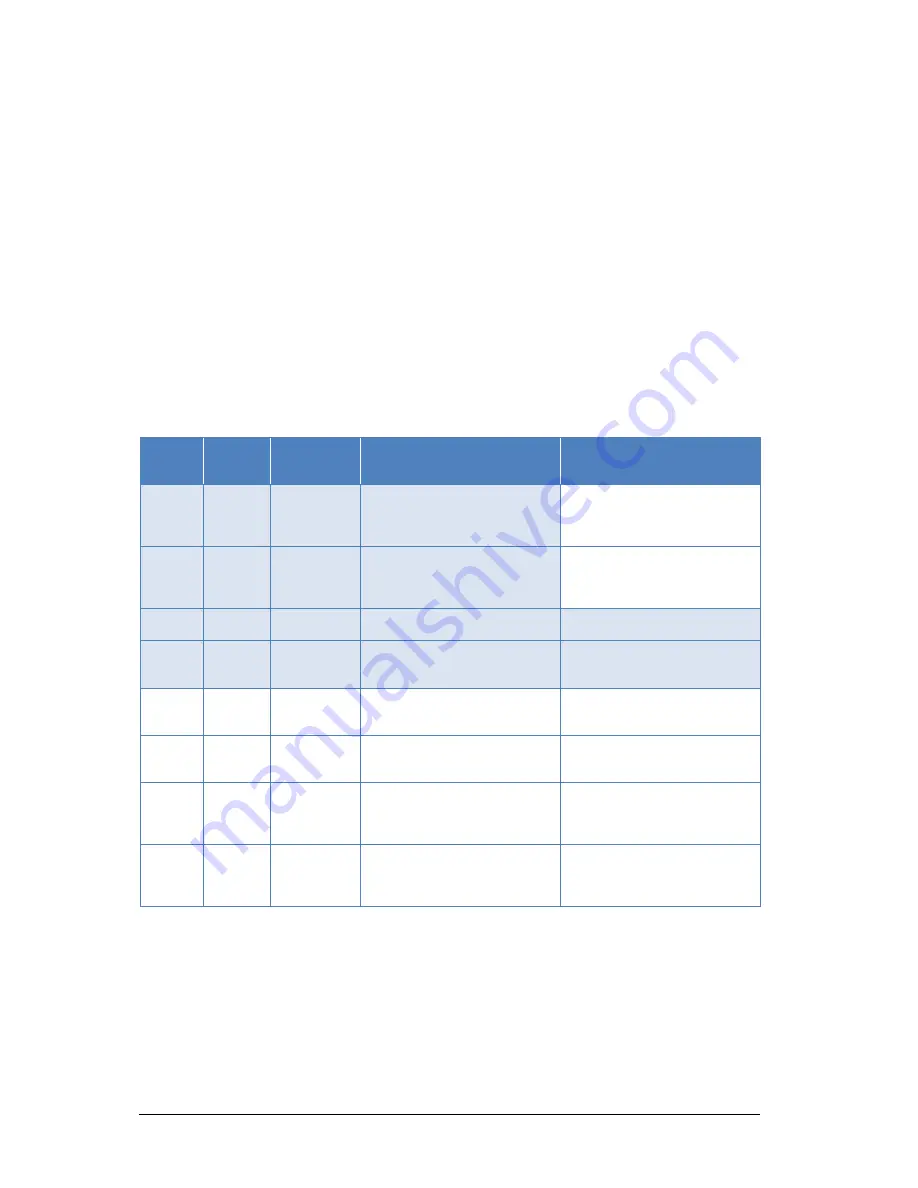

This can appear confusing. The conditions in the shaded rows of the table below provide

a true half-cycle test.

Familiarise yourself with why the others effectively result in a full-cycle movement. A

single cycle test is usually a better choice. Note that row conditions 3 and 4 under a full

cycle test (any number of counts) will also result in a half-cycle action.

Half-cycle tests will always end with the display reading the final angle that was set. To

re-run, the drive spindle must be returned to zero, or the displayed angle tared to zero.

CW

angle

ACW

angle

Start

direction

Action from tared zero

Press run button again –

without taring angle

+30º

zero

CW

Go CW to +30º and stop

Go to ACW angle (zero), then

CW to +30º (becomes a full

cycle)

zero

–

30º

ACW

Go ACW to

–

30º and stop

Go to CW angle (zero), then

ACW to

–

30º (becomes a full

cycle)

+30º

+30º

CW or ACW

Go to CW angle of +30º and stop No action

–

30º

–

30º

CW or ACW

Go to ACW angle of

–

30º and

stop

No action

+30º

zero

ACW

Go to CW angle of +30º and

return ACW to zero

Repeat action

zero

–

30º

CW

Go to ACW angle of

–

30º and

return CW to zero

Repeat action

+30º

-30º

CW

Go ACW to -30º, then through

tared zero to +30º and stop

Go ACW through tared zero to -

30º, then through tared zero to

+30º and stop.

+30º

-30º

ACW

Go CW to +30º, then through

tared zero to -30º and stop

Go CW through tared zero to

+30º, then through tared zero

to

–

30º and stop.

Summary of Contents for Vortex-dV 1.5 N.m

Page 1: ...Vortex dV Motorised Torque Testing System Operating Manual 431 468 02 May 2018 ...

Page 4: ...iv Mecmesin Vortex dV Operating Manual ...

Page 21: ...Vortex dV Operating Manual Mecmesin 17 Declaration of Conformity ...

Page 22: ...18 Mecmesin Vortex dV Operating Manual ...