Service manual 1533-2003-S

65 of 108

Version 1.0.2/2020

Medema Production A/S

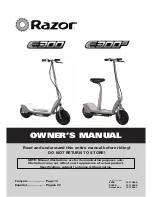

The plug from the potentiometer is now

free.

New potentiometer. Mount in reverse

order.

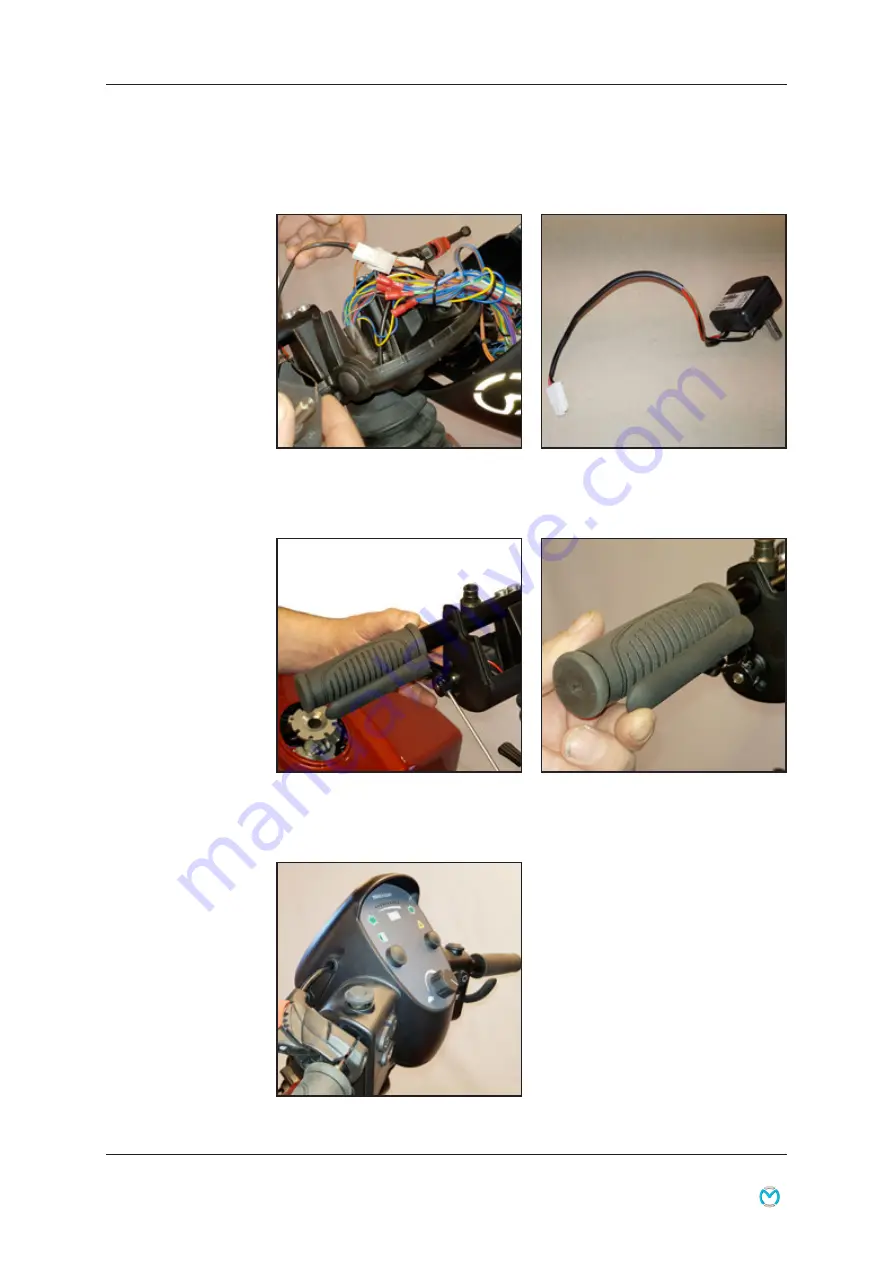

When the throttle handle is mounted,

hold it in position ”full speed” when you

tighten the stop screw again.

This means that the four-finger grip

should touch the handle while tightening.

Check that all functions are working

correct.