2.12

MD8000 Multimedia Transport System

MD8000 Rev. H

Class C

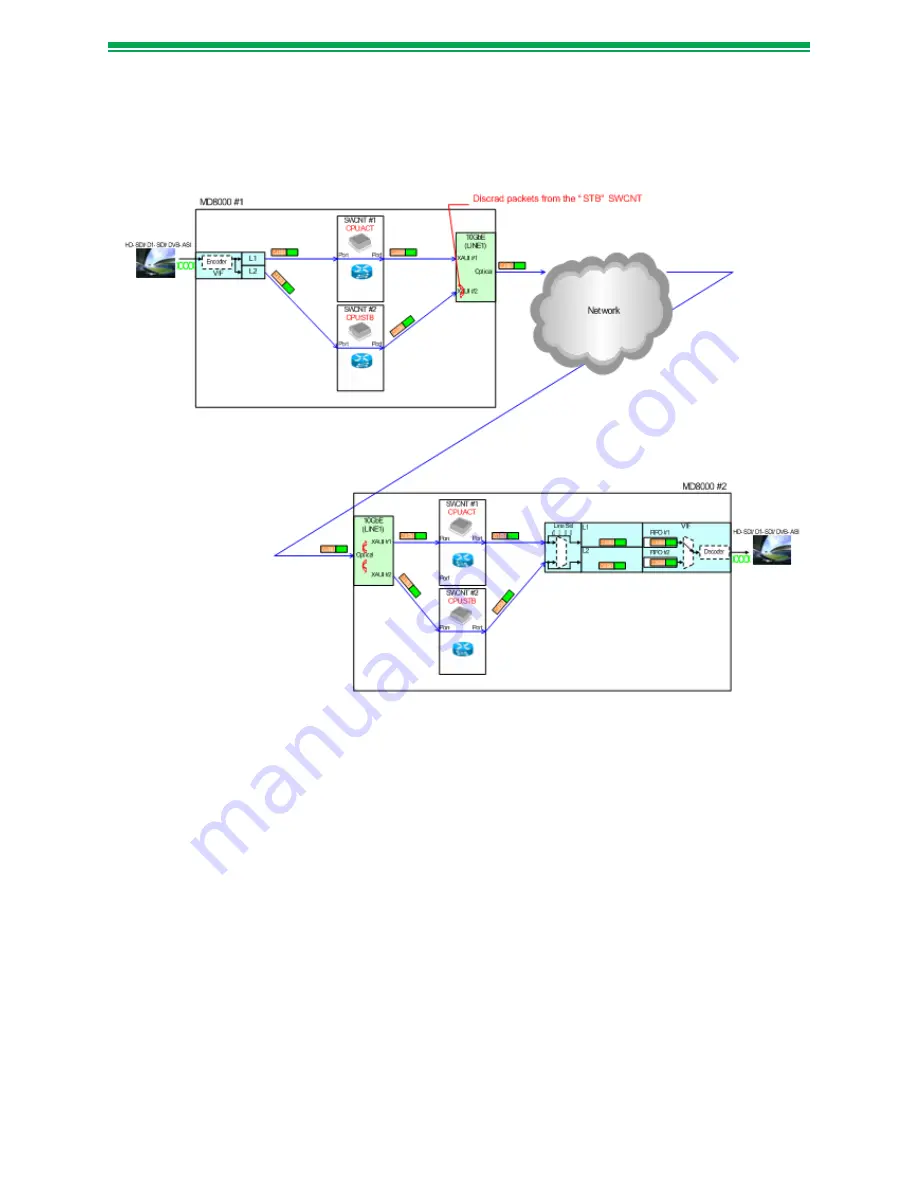

The

Class C

mode runs under the “

Dual SWCNT/Single Trunk

” configuration. This

configuration protects the system from a single SWCNT board failure. Figure 2-6 illustrates

the flow of packets.

Figure 2-6: Class C Mode Of Operation

In the originating System (#1), the Channel Service board duplicates the encapsulated video

signal with the same MAC address “M1-1” and delivers the same to #1 (CPU-ACT) and #2

(CPU-STB) SWCNT boards. (See

Dual SWCNT Operation, page 2.33

operation.) SWCNT #1 passes packets to the “Line 1” input of the Trunk board and SWCNT

#2 passes packets to the “Line 2” input of the same Trunk board. The Trunk board transmits

out to the network packets arrived through the “ACT” SWCNT board and discards all the

packets from the “STB” SWCNT board. The Trunk board continuously monitors the “ACT”

input-packet flow and if it drops off for a certain period of time, the board automatically

switches to use the packets from the “STB” stream.

In the receiving System (#2), a Trunk board duplicates the received packets and delivers the

same to both #1 (ACT) and #2 (STB) SWCNT boards. The #1 SWCNT board passes the

received packets to the “Line 1” input of the destination Channel Service board and the

#2 SWCNT board passes the received packets to the “Line 2” input of the same destination

Channel Service board. The output video signal is reproduced from either the “Line 1” or

“Line 2” stream.

Summary of Contents for MD8000 Series

Page 1: ...MD8000 Multimedia Transport System Operational Manual For Release 8 21 MD8000 Rev H ...

Page 2: ......

Page 3: ...MD8000 Multimedia Transport System Operational Manual For Release 8 21 MD8000 Rev H ...

Page 6: ......

Page 12: ...vi MD8000 Transport System MD8000 Rev H This Page Intentionally Left Blank ...

Page 20: ...1 8 MD8000 Multimedia Transport System MD8000 Rev H This Page Intentionally Left Blank ...

Page 56: ...2 36 MD8000 Multimedia Transport System MD8000 Rev H Figure 2 32 SWCNT 2 State Transition ...

Page 60: ...3 2 MD8000 Multimedia Transport System MD8000 Rev H This Page Intentionally Left Blank ...

Page 66: ...3 1 6 MD8000 Multimedia Transport System MD8000 Rev H This Page Intentionally Left Blank ...

Page 70: ...3 2 4 MD8000 Multimedia Transport System MD8000 Rev H This Page Intentionally Left Blank ...

Page 78: ...3 3 8 MD8000 Multimedia Transport System MD8000 Rev H This Page Intentionally Left Blank ...

Page 84: ...3 5 4 MD8000 Multimedia Transport System MD8000 Rev H This Page Intentionally Left Blank ...