30

1. Identify suitable locations to install the Straight Nozzles.

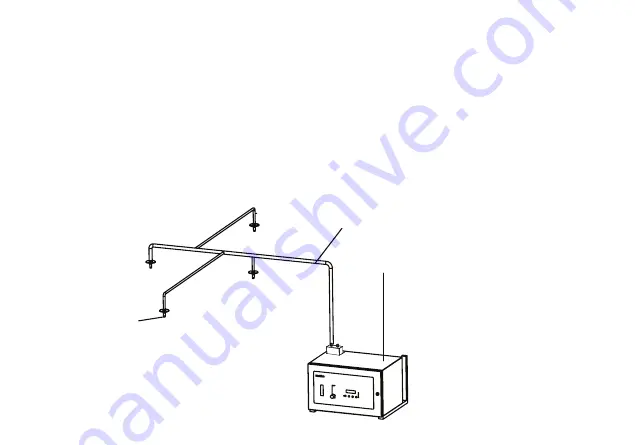

NOTE: The nozzles need a minimum clearance radius of 0.6m from any object (eg. walls, lightings,

speakers, sprinklers etc.) and at least 2m from return air vents

2. Plan a path for the FEP Tube starting from the device to the last Straight Nozzle.

3. Lay down the Electrical Conduits along the planned path.

4. Slot in the FEP Tube through the Electrical Conduits.

NOTE: Do not bend more than 30˚ when laying down the FEP Tubes as it will damage the tube

walls/restrict the Active Oxygen flow through the FEP Tubes.

5. Connect multiple Straight Nozzles along the FEP Tube path each with a T-joint.

6. Connect the FEP Tubes to the Straight Nozzles and device’s Reservoir outlet.

PRO AS300D/500D

Straight Nozzle

FEP tube inside the ½ inch electrical conduit