INSTALL THROUGH TANK FITTING:

STEP 1: Locate the hatch where the GS-12-Air mixer will be installed through and mark a penetration

point on the roof for the penetration fitting. When selecting a penetration location be sure to confirm

the following:

A. The penetration is not going to hit an internal structure.

B. The penetration is centered within a clear footprint of approximately 8-inch X 8-inch (20cmX20cm)

C. The penetration is within arms reach of the hatch.

STEP 2: Use a cordless drill with the 1-5/16 inch (33mm) hole saw and begin drilling a hole through

the tank roof. A small amount of food grade vegetable oil or water works well for lubrication of the

hole saw. Prior to completing the penetration, position a catch bucket below the penetration point to

catch filings and the hole cut out. If a catch bucket is not readily available, use the cardboard box the

hole saw and fittings came in to catch the filings and disc cut out from falling into the tank.

STEP 3: Thoroughly clean all surfaces around the penetration of any filings before removing

the catch bucket. The penetration is now ready for a sealant application and installation of the

penetration fitting.

STEP 4: Apply a healthy amount of sealant on all the surrounding surfaces of the penetration (interior,

exterior, and inner wall). This will prevent future corrosion of the roof around the fixture.

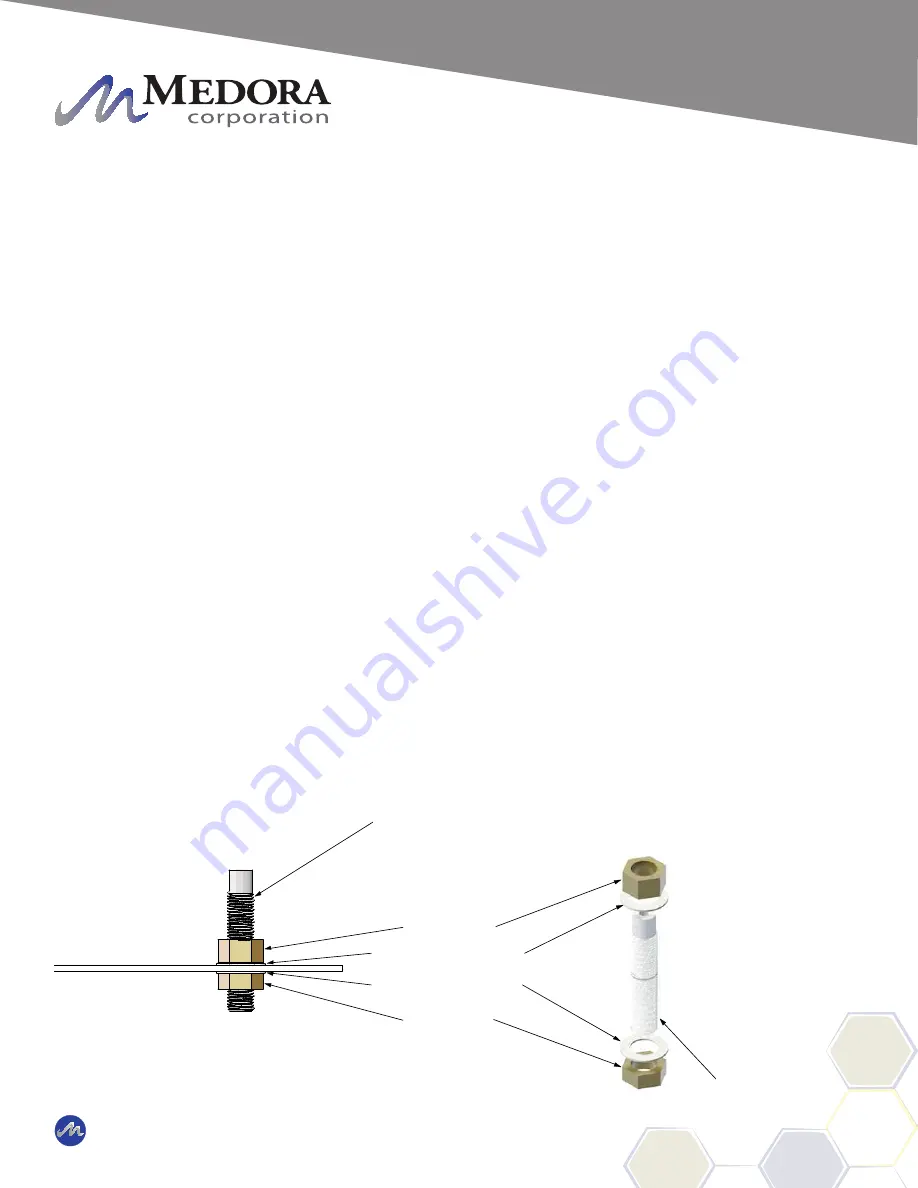

STEP 5: Install the penetration fitting as shown below so that there is an interior and exterior nut and

gasket in place prior to tightening the fixture to the roof. Adjust the height of the fixture so the top is

approximately 3-1/2 inches (9cm) above tank roof. Tighten jam nut to firmly secure the fixture to the

roof using a large channel lock and pipe wrench.

Penetration Fitting

THE INFORMATION CONTAINED IN THIS DRAWING

IS THE SOLE PROPERTY OF MEDORA

CORPORATION. ANY REPRODUCTION IN PART OR

AS A WHOLE WITHOUT THE WRITTEN PERMISSION

OF SOLARBEE, INC. IS PROHIBITED.

PART NO.

REV

TITLE:

PROPRIETARY AND CONFIDENTIAL

Fixture Bolt: Steel Tank Mount

FILE NAME

FixtureBolt_20161130

1 CORD BOLT PER SOLARBEE:

NUT/GASKET OD:

2.250"

THREADED FIXTURE OD:

1.250"

BORE REQUIRED:

1.250"

METAL TANK ROOF

INSIDE TANK

OUTSIDE TANK

BRASS NUT

HDPE WASHER SEAL

HDPE WASHER SEAL

BRASS NUT

316SS CORD BOLT

(3/4" NPT INTERNAL

THREADS FOR PV STAND

CONNECTION POINT)

316SS CORD BOLT

ASSEMBLED

VIEW

EXPLODED

VIEW

CROSS-SECTIONAL

VIEW

T316 SS FIXTURE BOLT: TANK PENETRATION ASSEMBLY

TANK PENETRATION IS SEALED WITH

HDPE WASHERS ACCOMPANIED BY

LEXEL® CO-POLYMER RUBBER-BASED SEALANT

Penetration Fitting

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | info@medoraco.com

Installation and Operation

GS-12-Air

10390_20191001

O&M_GS_12_Air_120V_10389_20191017 - 6