35

182_20161129

Technology Description:

Floating, solar powered, circulation equipment. Two mixing flows for maximum

nutrient (N and P) reduction, in addition to BOD/TSS reduction in partial mix and

facultative wastewater treatment systems. Day/night operation on solar only by

utilizing a battery to store excess daytime power for nighttime operation.

Flow Rates:

Flow rates at full speed at 10 feet (3 meter) diameter.

Direct Flow Rate - Day

3,000 gallons per minute, (12,000 Liters per minute).

Induced Flow Rate - Day

7,000 gallons per minute. (26,000 Liters per minute).

Combined Flow Rate - Day

10,000 gallons per minute. (38,000 Liters per minute).

Combined Flow Rate - Night

10,000 gallons per minute (38,000 Liters per minute).

Lower Mixed Zone Flow Rates:

Flow rates at full speed at center of machine.

Direct Flow Rate - Day

150 gallons per minute. (600 Liters per minute).

Direct Flow Rate - Night

150 gallons per minute (600 Liters per minute).

Machine Size/Weight:

Assembled machine is 16 feet (5m) in diameter and weighs 850 pounds (380kg).

Shipping Size/Weight:

Machine can be crated and shipped in a 87 inch (2.2 m) wide X 87 inch (2.2 m)

long X 65 inch (1.7 m) high crate, estimated shipping weight is 1500 pounds (680

kg). Hose lengths greater than 20 ft (6 m) may require additional crating.

Materials of Construction:

316 stainless steel construction. Foam-filled high-density polyethylene (HDPE)

floats. Thermoplastic rubber, stainless steel reinforced intake hose. Concrete

mooring blocks are encapsulated in HDPE.

Drive System:

High torque, direct drive (no gearbox), low voltage brushless D.C. motor.

Power Supply/Control System:

PV solar panels are protected from bird fouling with bird deterrent kit.

PV Solar Panels

3 X 80-watt photo voltaic solar panels orientated in triangular pattern. On-board

battery storage for 24-hour operation.

Electronic Controller

Digital solid-state controller, mounted in weather-tight (NEMA 4X) enclosure with

externally fused disconnect. SCADA output through RS-232 serial communication

(Modbus RTU), DB9 male connection point inside enclosure. Wireless options

available, not included.

Wiring

Corrosion-resistant industrial cord with molded watertight connectors that are

indexed to prevent improper wiring.

Rotating Assembly:

Removable assembly with easy access to motor and digital controller. Impeller

handles 4-inch (10cm) spherical solids. Oil-filled (food grade) teflon freeze sleeve

with o-rings, shaft. Rotational indicator on shaft.

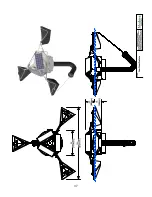

Flotation System:

Three floats in triangular pattern each with an adjustable float arm for proper

vertical positioning, total float buoyancy of 1,450 pounds (660kg).

Upper Mixed Zone Fluid Intake

Assembly:

Bolted to bottom of structural assembly.

Intake Type

Fixed horizontal plate with 12-inch (31 cm) openings.

Intake Depth Adjustment

No adjustment necessary. Horizontal inflow from 25in (64cm) below distribution

dish.

Lower Mixed Zone Fluid Intake

Assembly:

Bolted to bottom of structural assembly.

Hose System

12-inch (31 cm) diameter X 20 feet (6 meter).

Intake Type

Inverted bell shape strainer with 3-inch holes (7.6 cm).

Intake Depth Adjustment

There is no adjustment necessary for fluctuations in water level. Weight and

flotation of the ‘J’ bend of hose keeps intake above sludge at all operating depths.

Strainer can be chained up higher if desired.

Anchoring:

(1) Two mooring blocks tethered together with SS chain and attached to structural

member on unit or (2) Tethered to shore with SS cable.

Ice Protection:

Freeze sleeve and positive pumping under distribution dish to maintain circulation.

Minimum Operating Depth:

36 inches (0.9 m). No damage to machine or bottom of reservoir when run dry in

shallow water.

Accessories Available:

(1) Supplemental Shore Power Kit, (2) Chemical Injection Kit, (3) Marker Light Kit

Life/Maintenance/Warranty:

Expect 25-year life, minimal maintenance. Limited 2-year parts and conditional

labor warranty. Limited 25 year photovoltaic module manufacturer performance

warranty and 10 year motor warranty.

SB10000DM DUAL MIX FEATURES

Patent Pending

Subject to change without notice.

Medora Corporation • 3225 Hwy 22 • Dickinson, ND 58601

+1 866 437 8076 • Ph +1 701 225 4495 • Fax +1 701 225 0002 • www.medoraco.com

© 2017 Medora Corp.