www.medoraco.com | 866 - 437 - 8076 | info@medoraco.com

10267_20181113

If the distributor dish lip is too low, the water

coming off the lip will flow just underneath the

surface of the pond and the surface will not be

renewed.

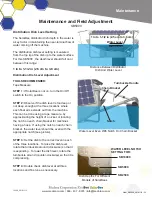

Each float arm is connected to the central

machine structure with 1 bolt and 1 pin. Each

float is connected to the float arm by 2 pins. The

turnbuckle can be removed from the float arm by

pulling a pin, but should only be done when the

unit is resting on the shore.

If re-attaching the turnbuckle to the float arm, be

sure that each threaded end of the turnbuckle

together are screwed all the way in or all the way

out before re-attaching. If threaded ends are not

equally expanded or collapsed before fixing the

ends, the turnbuckle will have limited adjustment.

Floats

- The SolarBee has 3 floats, made from

high density Polyethylene. The floats are filled

with a Polystyrene closed-cell foam for long term

buoyancy. The floats have a uniquely designed

shape to:

• Minimize the interference with the water

flow on the surface coming off the

distributor dish.

• Have a low profile above the water for

minimizing wind resistance and

offering less exposure to vandalism.

• Avoid being crushed by ice pressure.

• Provide extra buoyancy when needed

without going much deeper into the

water.

Features

Features

SB5000

Float Arm Connection Points

Pin

Pin

Pin

Pin

Float

CAUTION: DO NOT REMOVE

ANY FLOAT ASSEMBLY

PINS OR BOLTS WHILE THE

SOLARBEE IS FLOATING IN

THE WATER! THE SOLARBEE

MUST BE RESTING ON

THE GROUND OR SAFELY

SUPPORTED TO RELIEVE

THE FORCES ON THE FLOAT

ASSEMBLY STRUCTURES

PRIOR TO DISASSEMBLY!

FAILURE TO FOLLOW THIS

WARNING COULD LEAD TO

SINKING THE SOLARBEE,

SERIOUS INJURY!

O&M_SB5000_20181113 - 13