EN

45

• Wipe the rotary hammer drill’s exterior using a clean cloth after each use.

TROUBLESHOOTING

PROBLEM

PROBABLE CAUSE

REMEDY

The rotary hammer drill

won’t start.

The cable is not connected.

Check that the cable is connected.

No current at the electrical

socket.

Check the current at the electrical socket.

Shut off the tool and check the fuse if

there is no current at the socket. Check

that the power circuit is appropriate for

the rotary hammer drill and that there

are no other loads connected to the

circuit if the fuse has been triggered.

The rotary hammer drill’s

thermoswitch (if there is one)

has been triggered.

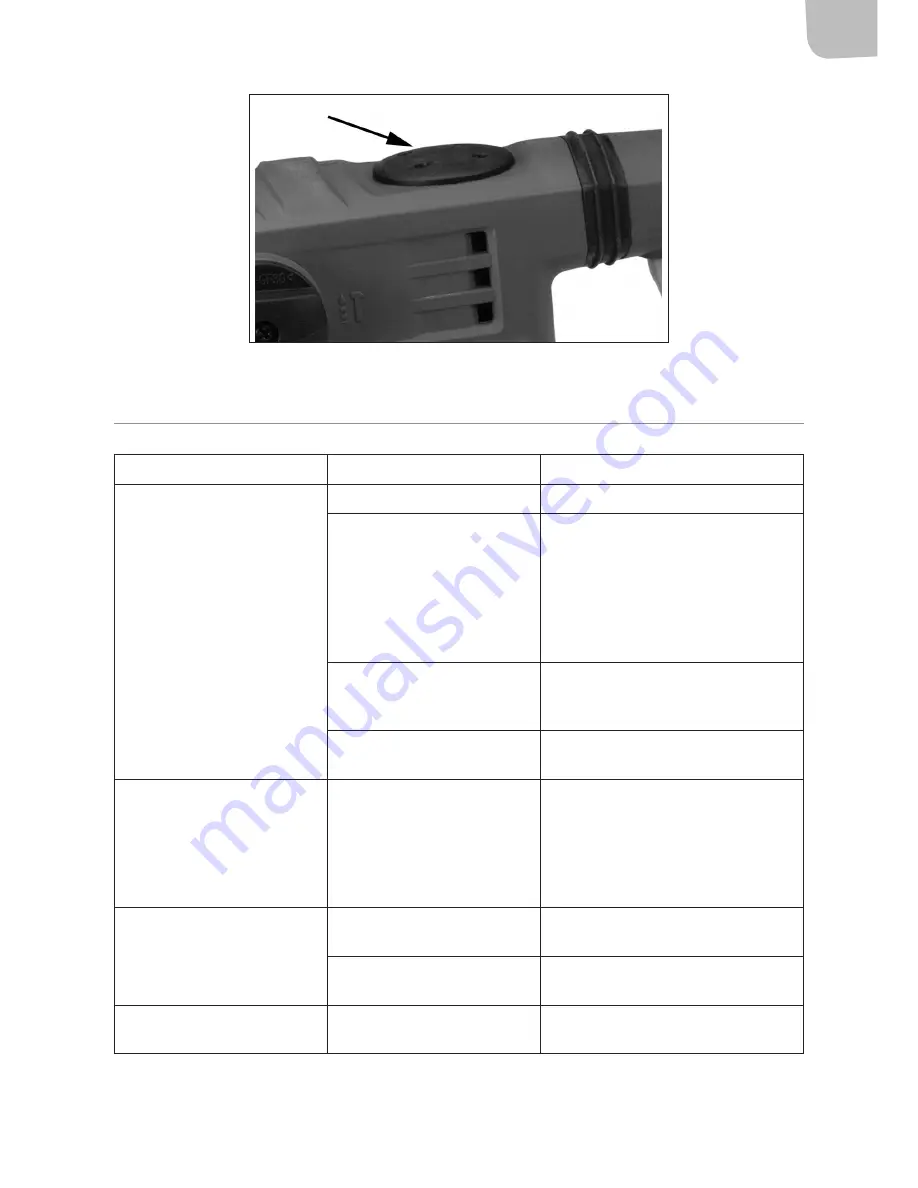

Turn off the rotary hammer drill and let

it cool. Press the reset button on the

rotary hammer drill.

Internal damage or wear (e.g.

carbon brushes or breakers).

Have a technician service the rotary

hammer drill.

The rotary hammer drill

rotates slowly.

The extension cable is too long

or the cable capacity of the

extension cable is too small.

Connect the rotary hammer drill to

an electrical socket close by so that

an extension cable is not needed. Use

suitable extension cable with the right

cable area suitable for the length and

load.

The output diminishes

over time.

Dulled or damaged cutting tool.

Make sure that the cutting tool is kept

sharp. Replace as needed.

Do not use worn or damaged

carbon brushes.

Have a qualified technician replace

carbon brushes.

Loud noise or rattling sound.

Internal damage or wear (e.g.

carbon brushes or bearings).

Have a technician service the rotary

hammer drill.