EN

46

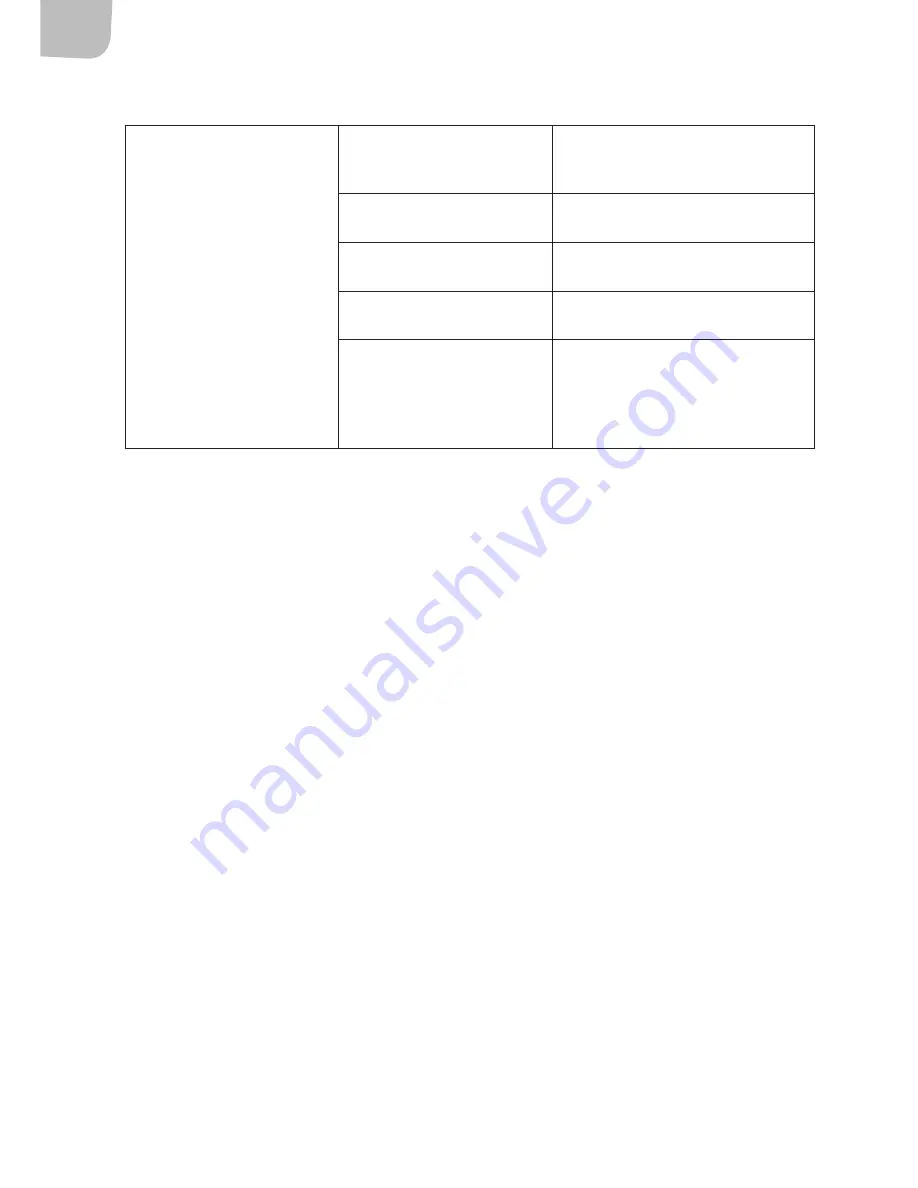

Overheating.

The rotary hammer drill is

pressed too hard against the

work piece.

Let the rotary hammer drill work at its

own pace.

The cutting tool is incorrectly

mounted.

Check how the cutting tool has been

mounted.

Dulled or damaged cutting tool.

Make sure that the cutting tool is kept

sharp. Replace as needed.

The motor’s ventilation holes

are clogged.

Blow away dust from the motor with

compressed air.

The extension cable is too long

or the cable capacity of the

extension cable is too small.

Connect the rotary hammer drill to an

electrical socket close by so that an ex-

tension cable is not needed. Use suitable

extension cable with the right cable area

suitable for the length and load.

NOTE!

Always follow the safety instructions when troubleshooting and carrying out maintenance.

Disconnect the rotary hammer drill from the mains before maintenance.