ENGLISH

19

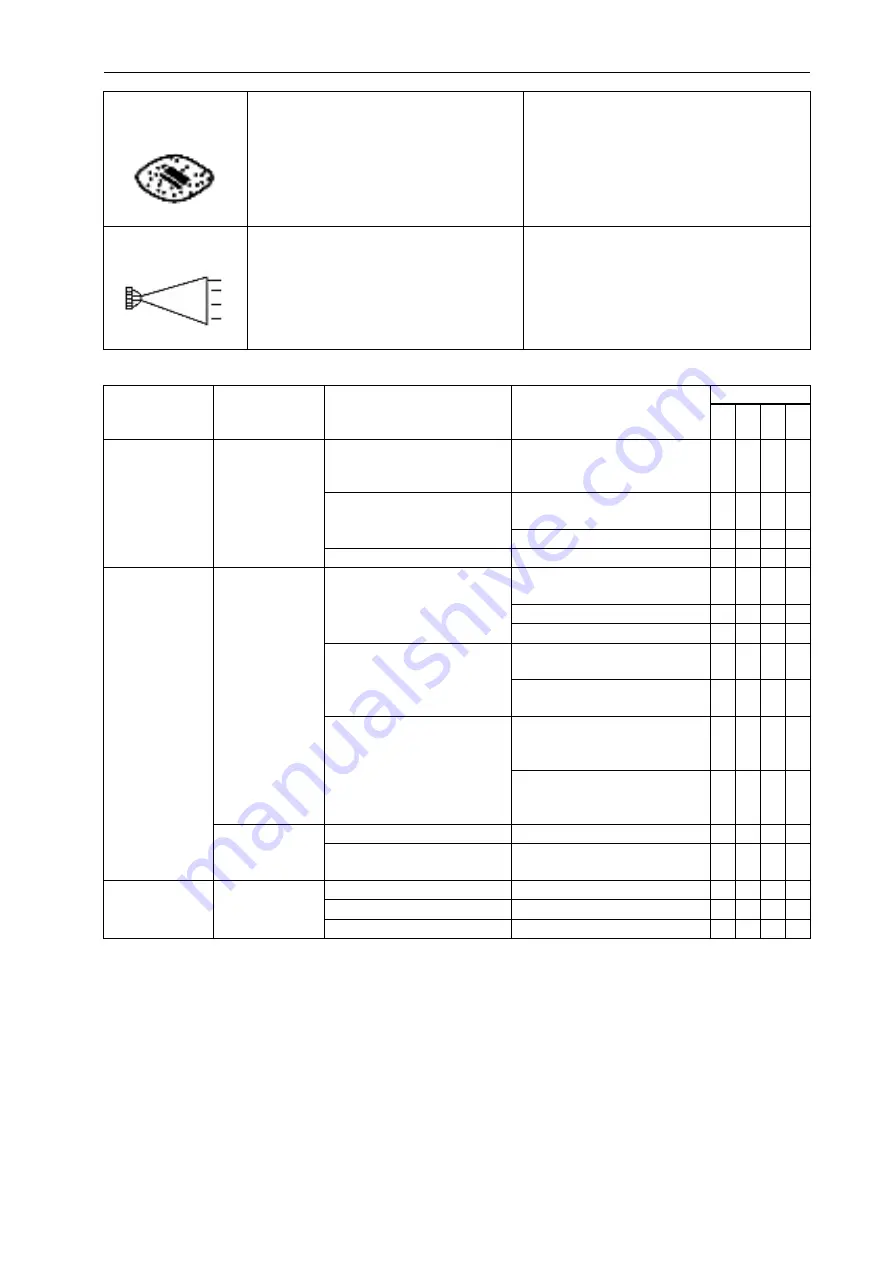

Thicker in the

middle

1.

Paint viscosity too high.

2.

Insufficient paint flow.

1.

Add solvent to reduce the viscosity.

2.

Increase the fluid flow.

Splashing

1.

Paint nozzle and paint needle are

not assembled properly.

2.

The first part of the trigger

movement, when only air passes,

is too small.

3.

Paint build-up in the air cap.

1.

Clean or replace the paint nozzle

and paint needle unit.

2.

Replace the paint nozzle and paint

needle unit.

3.

Clean the air cap.

R1: Tighten. R2: Adjust. R3: Clean. R4: Replace parts.

Problem

Affected

component

Component to check

Cause

Action

R1

:

R2 R3 R4

Air leakage

from the tip of

the air cap.

Air vent

Air vent

The seat is dirty or

damaged.

O O

Air valve seat

The seat is dirty or

damaged.

O O

Air valve spring worn

O

O-ring

Damaged

or

worn

O

Paint leakage Paint nozzle

Paint nozzle/paint needle

The seat is dirty,

damaged or worn

O O

Paint flow knob loose

O

Needle spring worn

O

Paint nozzle/spray gun

body

Not

tightened

sufficiently

O

The seat is dirty or

damaged.

O O

Paint

nozzle

seal

The needle does not

return, as the seal is

too tight

O

O

The needle does not

return, due to paint

build-up on the needle

O O

Paint needle

Needle seal/needle

Wear

O O

Seal

seat

Not

tightened

sufficiently

O

No paint flow

Spray gun tip Paint flow knob

Opening

too

small

O

Hole in the nozzle tip

Clogged

O

Paint

filter

Clogged

O O

Jula reserves the right to make changes. In the event of problems, please contact our service

department.

www.jula.com