27

ENGLISH

USE

Installation

Cables with a larger cross-sectional area must

be used when working with long welding handle

cables, to counteract voltage loss. Otherwise the

welding machine will not work properly.

Connection of voltage supply cable

1.

Make sure to connect the wires to the

correct terminals.

2.

The input voltage is 220 VAC single-phase.

3.

Regularly check by measuring, that the

switch and voltage supply cable are

correctly connected and free from oxide.

Connection of welding handle cable

For TIG welding the connection is made in the

same way as above. For MMA welding the connection is made as below.

1.

The machine has one red and one black cable on delivery. Connect the black cable to the welding

handle and the red cable to the earth clip. Tighten with a spanner to make the connection safe and

secure, otherwise there is a risk of burn damage.

2.

Incorrect connection of the earth clip cable can also result in damage to the mains supply or trip

the mains fuses. Make sure to connect the cables with the right polarity. For welding with acidic

electrodes the workpiece is connected to + and the welding handle to -. For welding of stainless steel

the welding handle is connected to + and the workpiece to -.

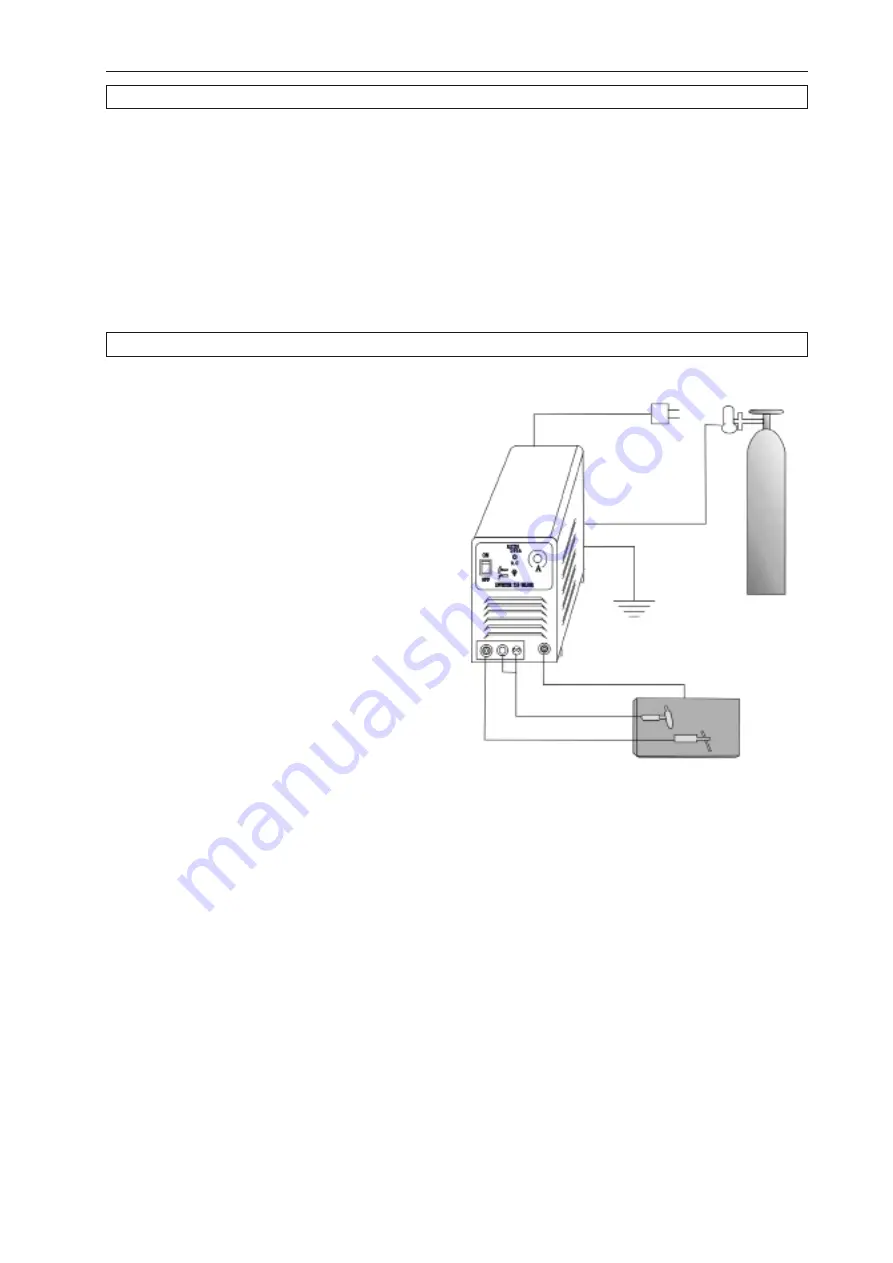

230 VAC

TIG welding handle

Workpiece

MMA welding handle

Earth

Flow regulator

Gas cylinder

DESCRIPTION

MMA/TIG welding machine with function selector.

During MMA welding (manual metal arc welding) the machine works with constant power and arc pressure

regulation. With a normal arc length the power will therefore not vary during moderate variations of the

arc length, which ensures a stable arc and uniform welding. If the arc becomes very short, or the arc

voltage very low, the power is allowed to increase so that the electrode fusing becomes faster and the arc

length returns to normal. If the arc becomes so short that the arc voltage becomes very low (risk of short

circuiting), the power will be reduced to avoid short circuiting, splatter and burning.

For TIG welding the machine varies the arc voltage to maintain a constant welding current. The current is

automatically reduced to 0 in the event of short circuiting to avoid the workpiece being contaminated by the

tungsten electrode.