29

ENGLISH

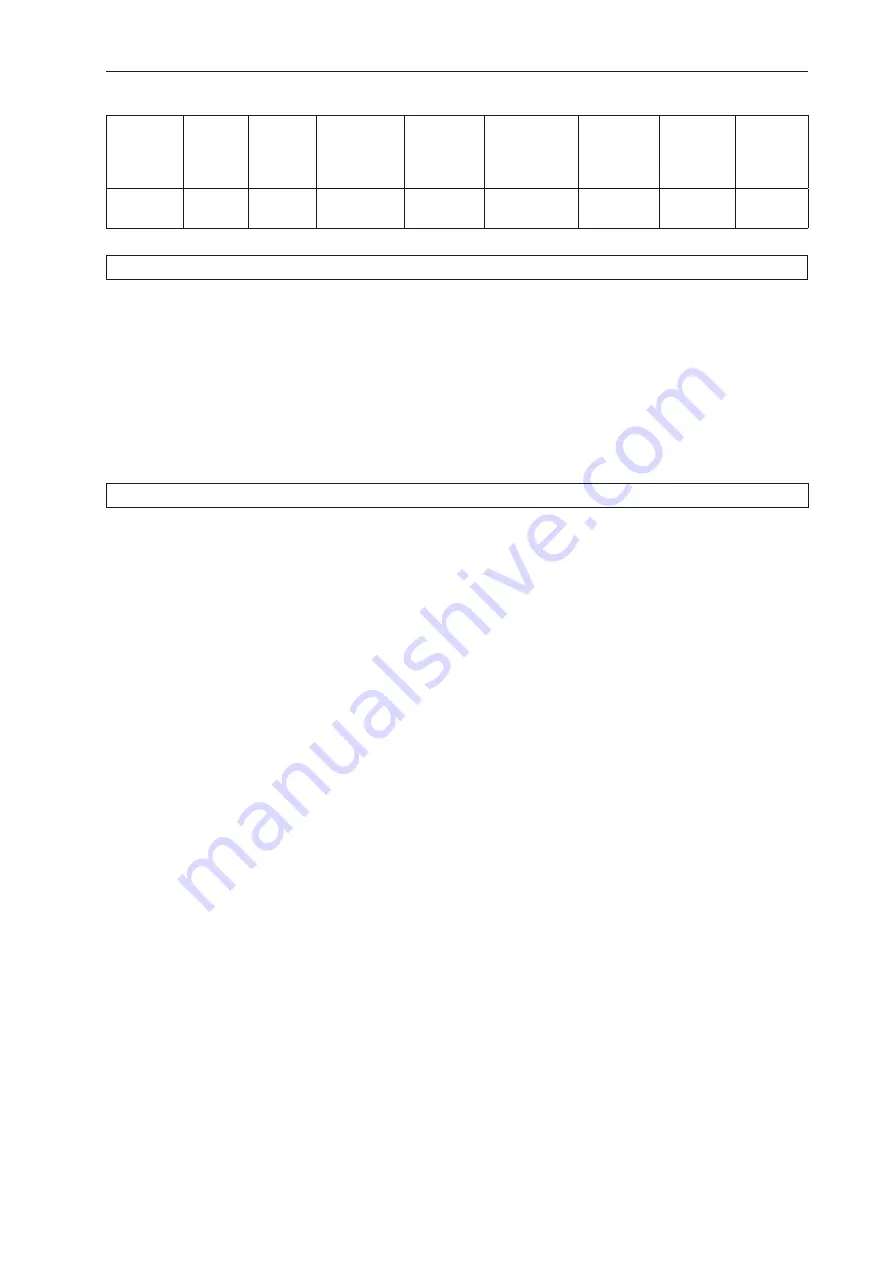

Settings for aluminium and aluminium alloys, TIG

(guidance only)

Plate

thickness

(mm)

Type of

joint

Number

of beads

∅

tungsten

electrode

(mm)

∅

wire (mm)

Preheating

temperature

(°C)

Welding

current (A)

Gas flow

(l/min)

∅

gas

cover

(mm)

1,5

I

1/0

2

1,6–2,0

–

50–80

7–9

8

2,0

1/0

2–3

2,0–2,5

–

50–80

8–12

8–12

1.

Clean regularly with compressed air. When working in smoky and/or contaminated environments,

clean the machine every month.

2.

Use compressed air at low pressure, otherwise the machine could be damaged.

3.

Regularly check that gas connections and electrical connections are correctly implemented and free

from oxide. Remove any oxide with sandpaper and tighten the connections.

4.

If the machine has got wet, it should be insulation tested first before using it. Check also the insulation

between the casing and live parts.

5.

If the machine is not going to be used for some time, it should be stored in a dry place in the original

pack.

MAINTENANCE

TROUBLESHOOTING

Ambient conditions, voltage supply, or parts and accessories are potential sources of problems. Check the

ambient conditions first if problems arise.

Black weld

If the weld is black this means it is not being protected properly by the shielding gas.

1.

Check that the gas cylinder valve is open and that there is sufficient gas pressure. Fill up the gas

cylinder if the pressure is less than 0.5 MPa.

2.

Check that there is a sufficient flow of gas. The gas flow can be adjusted to the welding current, but

must always be sufficient to protect the weld. The gas flow should never be less than 5 l/min.

3.

The easiest way to check the gas flow is to feel with your hand that gas is flowing out. The welding

results will deteriorate if the hose is blocked or leaking, or if the gas is contaminated.

4.

Strong draughts can also impair the results.

5.

Pulse width set too low.

The arc is difficult to ignite and extinguishes easily.

1.

Use good quality tungsten electrode. Low quality electrodes have inferior electrical properties.

2.

The welding arc will be difficult to ignite and easily goes out if the tungsten electrode is not correctly

connected.

Unstable welding current

This could be because of the following reasons.

1.

Mains voltage fluctuates.

2.

Interference from mains supply or other electrical equipment.

Maintenance and repairs must only be carried out by qualified personnel with welding certificate.