EN

125

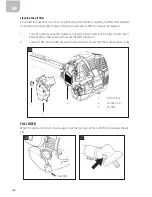

BEVEL GEAR

• The bevel gear is filled with the right quantity of grease at the factory. However, before using the

machine you should check that the bevel gear is filled three-quarters full with grease (Figure 27).

• The grease in the bevel gear does not normally need to be changed except if repairs are carried out.

SPARK PLUG

• The spark plug condition can be negatively affected by:

– Incorrect carburettor adjustment

– An incorrect fuel mixture (too much or incorrect type of oil).

– A dirty air filter.

• These factors cause deposits on the spark plug electrodes, which may result in operating

problems and starting difficulties.

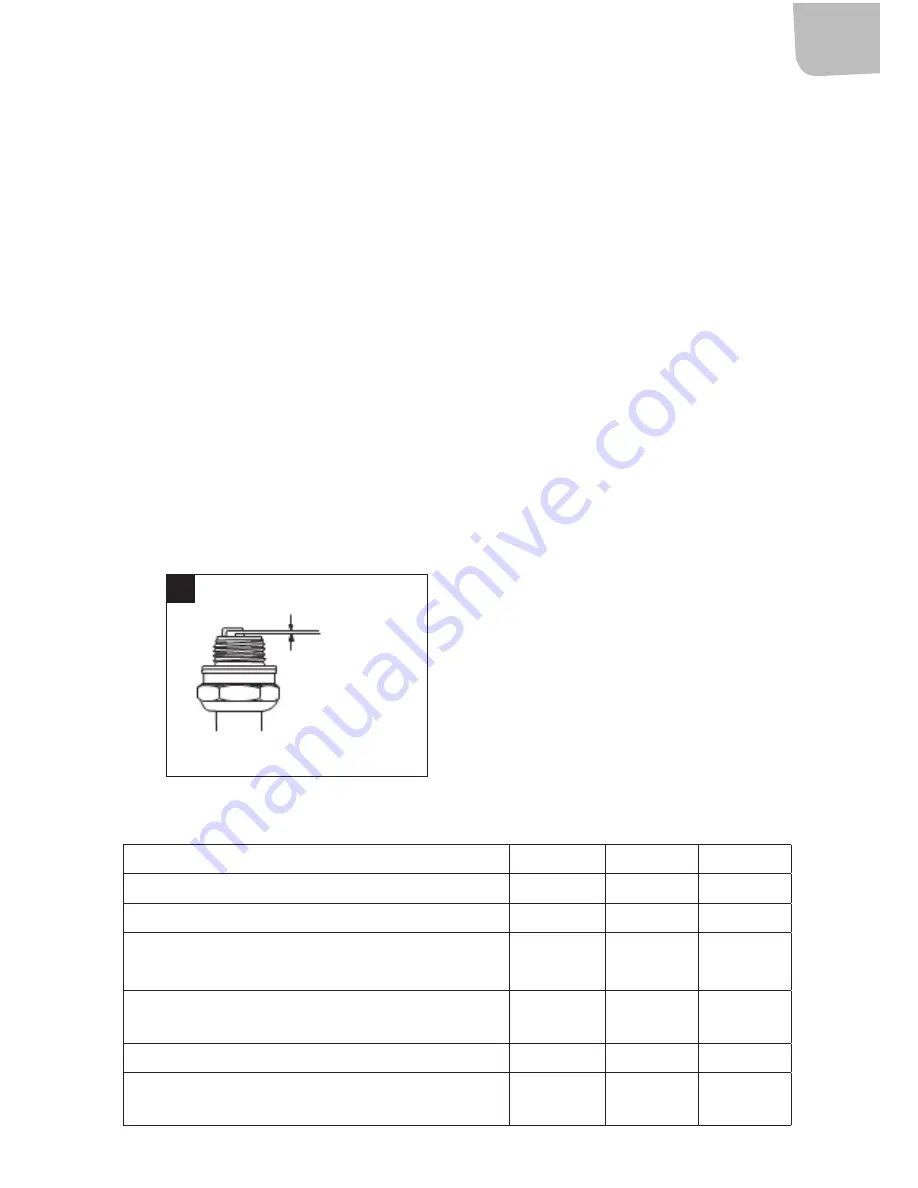

• If the brush cutter is low on power, difficult to start or runs poorly at idle speed, always start

by checking the spark plug. If the spark plug is dirty, clean it and check that the electrode gap

is 0.6-0.7 mm (Figure 28). The spark plug should be replaced after about a month in operation

or earlier if necessary.

NOTE!

Always use the recommended spark plug type. Use of the wrong spark plug can damage

the piston/ cylinder. Check that the spark plug is fitted with a suppressor.

MAINTENANCE SCHEDULE

Maintenance

Daily

Weekly

Monthly

Clean the outside of the machine.

x

Check that the harness is not damaged.

x

Make sure the throttle trigger lock and the throttle

function correctly from a safety point of view.

x

Check that the handle and handlebar are undamaged

and secured correctly.

x

Check that the stop switch works correctly.

x

Check that the cutting attachment does not rotate

when idling.

x

0.6 – 0.7 mm

28

Summary of Contents for 721-349

Page 101: ...EN 101 Open the choke...

Page 127: ......