19

10. Troubleshooting

Air flow

Problems with compressed air flow can be caused by:

1. Air pressure too low – increase air pressure at the relevant regulator

2. Undersized compressed air lines – replace pipes with correct sizes, see

section 5

3. Blocked compressed air line – remove blockage

4.

Insufficient compressor size – Check compressor size for fitting Cabinet

Cooler

Air Temperature

Problems with air temperature can be caused by:

1.

Incorrect generator fitted – Check and replace generator, see section 7

2. Ambient compressed air temperature too high – Check compressed air

temperature and use cooler if necessary

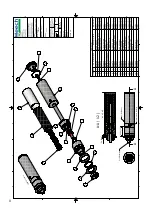

3. Loose/missing parts – Check all Cabinet Cooler parts are screwed in tightly

and there are no missing parts.

4. Water vapour in the compressed air supply – Check compressed air supply

5. Air pressure too low – increase air pressure at the relevant regulator