MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

www.mefe.com.au | info@mefe.com.au

Page 9

+617 3283 4536

Free AU 1800 669 006

5.5

Maintenance and Cleaning Continued

Cleaning should remove dirt and sediments, which left for too long on a stainless steel surface may initiate corrosion and tar-

nishing of the surface. In a highly contaminated or aggressive environment (seaside towns, rooms of increased humidity and

temperature, rooms requiring frequent use of disinfectants, in particular containing chloride compounds), cleaning should be

done more frequently. The frequency of cleaning should be empirically determined.

In order to prevent a surface of stainless steel equipment from being destroyed due to inappropriate maintenance, the follow-

ing guidelines should be complied with:

The following should not be used: agents containing chlorides and bleach or –

under any circumstances

-

silver cleaners.

-

Steel wool, sand paper, rough cleaners, scouring, grinding and polishing powders, etc. are not to be used as they scratch the

surface.

Steel pads for scouring or wire brushes can not be used –

they can leave sediments of carbon steel on the surface which will

eventually lead to material rusting.

First discolouration and dusts appearing during material use can be removed with a regular piece of cloth, chamois leather or

a nylon sponge in case of higher contaminations.

If iron particles generated during installation, etc. appear on stainless steel components, they should be immediately re-

moved. Such particles corrode, thus they can break the passive layer protecting stainless steel, leading to corrosion as a result.

Such sediments should be removed mechanically or with stainless steel cleaning agents.

-

If there are pits on a component, they should be pickled with acid or removed mechanically.

-

Local discolouration, grease marks –

if small, they can be removed with soap water.

-

Products for cleaning stainless steel and alcohol

-

based preparations can be used for cleaning –

they do not pose a threat

to the corrosion properties of stainless steel.

-

After cleaning, it is always recommended to polish the surface with a dry piece of cloth.

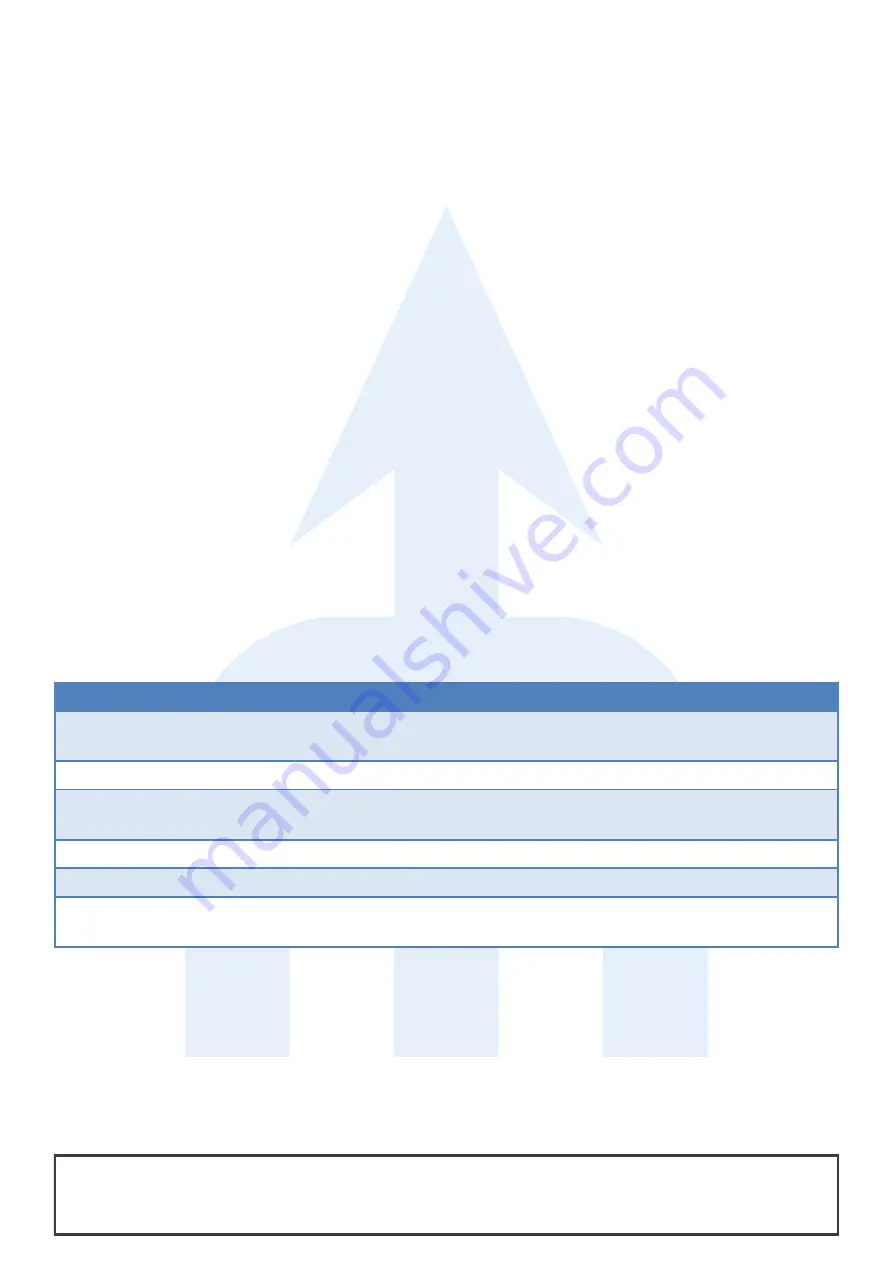

The table below presents the most frequent types of contaminations and methods of handling:

The frequency of cleaning components made of stainless steel is individual –

it all depends on the degree of wear and contam-

ination. It should be done in frequent intervals so as to reduce the risk of stainless steel component rusting. The frequency of

cleaning of stainless steel devices is analogous to the frequency of cleaning household sinks, stainless steel.

Contaminations:

Cleaners:

Finger Marks

Water with soap and detergent

Glass cleaning agents without chlorides

Lime Sediment

Vinegar

-

water solution

Oil and Grease

Alcohol based agents (only with methyl alcohol, isopropyl alcohol)

Solvents, e.g. acetone

Paints

Agents for removing paint coating, based on alkaline compounds / solvents

Cement and Mortar

Solvent containing a small amount of phosphoric acid, then water

Iron Particles

-

from tools / structural steel con-

tact

At an early stage—mechanically

If pits appear—with pickling and passivating pastes