EN

R

7

PREVENTIVE MAINTENANCE

IMPORTANT:

The biggest problem that causes product failure is dirt. Keep it clean and well lubricated to prevent any foreign

body from entering the hydraulic circuit. If you have been exposed to rain, snow and/or sand you must clean it before use.

1. Store in a well-protected area where it is not exposed to corrosive vapours, abrasive dust, or other harmful elements.

2. Lubricate moving parts regularly.

3. Change the oil at least once a year. Dismantle the hydraulic unit and with the piston fully retracted, remove the filler plug and

drain its contents into a container. With the hydraulic in a horizontal position, proceed to introduce the necessary volume for

each model as indicated in these instructions. Avoid the entrance of any dirt with the new oil.

IMPORTANT: The use of alcohol or brake fluid can damage the seals and cause the product to fail.

4. Check the product before each use. Take appropriate action if you see any of these occurrences:

5. Keep warning labels and instructions clean and legible. Clean outer parts with mild soap.

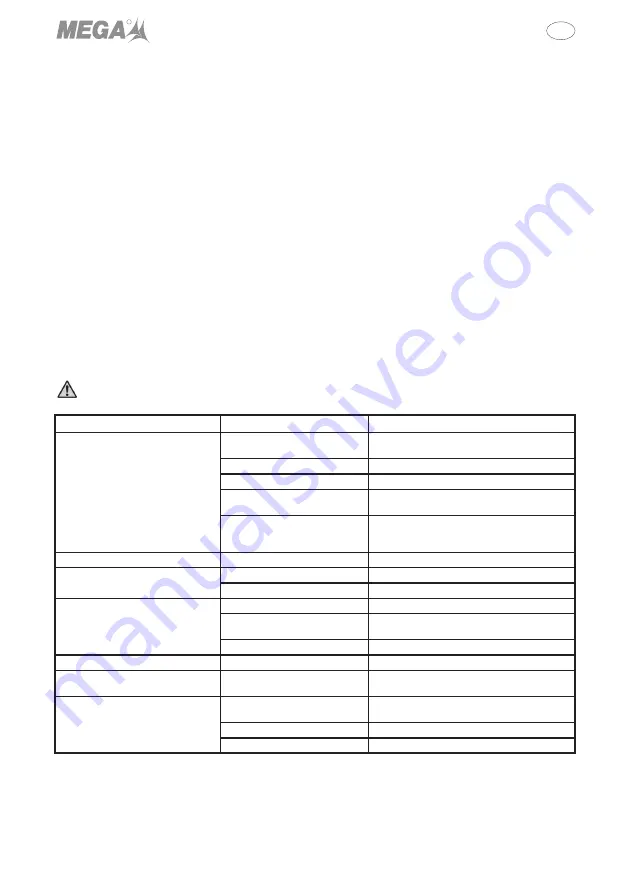

TROUBLESHOOTING GUIDE

Repairs must be carried out in a clean environment by qualified personnel who, through their training and experience, are familiar

with the hydraulic systems used in these appliances.

CAUTION: In order to prevent possible accidents, all inspections, maintenance and repairs must be carried out

when it is not loaded, when it is not in operation.

PROBLEM

CAUSE

SOLUTION

It does not lift the load.

Discharge is open.

Check that the discharge is closed.

Discharge needs to be cleaned.

Low level or no oil.

Fill with oil and purge the circuit.

Air in system.

Purge the circuit.

Load is above product capacity.

The load to be lifted should never exceed the rated

capacity.

Discharge valve and/or

overpressure valve not functioning

properly.

Clean to remove any internal dirt.

Replace hydraulic oil.

Partially raises the load.

Too much or too little oil level.

Check oil level.

Load rises slowly.

Pump does not work properly.

Check pump vessels.

Leaks from joints.

Replace joints.

Lifts the load but does not hold it.

Hydraulic leaks.

Check joints.

The valves are not working

properly.

Inspect valves. Replace if necessary.

Air in system.

Purge the circuit.

Leak from hydraulic.

Damaged joints or rings.

Replace joints or rings.

Does not descend.

Closed discharge.

Open discharge. It will be necessary to clean the

discharge.

Slow descent.

Damaged hydraulic inside.

Send the article to an authorised repair

workshop.

Return spring damaged.

Replace the discharge.

Noise on moving parts.

Lubricate moving parts.

a. Damaged hose

c. Oil leaks

e. Loose components

b. Damaged structure

d. Damaged pistons

f. Modified equipment

10130001001.05.

Abr

.20

parts in accordance with local regulations.

3.11 Both the repair kit, which exclusively contains the retainers and the spare part sets must be ordered using the reference

assigned in the table.