●

The expansion vessel must be connected between the cold water combination

valve and the cylinder.

●

The location of the expansion vessel should allow

access to recharge the pressure as and when necessary.

●

A suitable draining

tap should be installed in the cold water supply to the cylinder between

the expansion valve and the heater at as low a level as possible.

●

It is

recommended that the outlet point of the drain pipework be at least 1 metre

below the level of the heater (this can be achieved by attaching a hose to the

drain tap outlet spigot).

Cold water control pack CAUTION

●

The expansion vessel pressure must be set in accordance with the inlet

pressure set on

the pressure reducing valve.

●

Flush supply pipework before connection to remove all flux and debris prior

to fitting the

inlet controls.

Failure to do this may result in irreparable damage to the controls and will

invalidate any

warranty.

●

The cold water control pack can be connected anywhere on the cold water

cylinder supply prior to the expansion vessel.

●

The control pack incorporates

the strainer, check valve, core unit and expansion relief valve.

●

The valve

can be fitted in any orientation to suit the installation as long as the valve is

installed with the direction of flow arrows pointing in the correct direction.

●

The expansion relief valve should be installed with the discharge pipework

in either the horizontal position or facing downwards.

●

No other valves

should be placed between the cold water combination valve and the cylinder.

●

The blank plastic plugs in the body of the pressure relief valve are pressure

gauge connections to enable pressure monitoring to be carried out, should the

system develop a fault. It is recommended that these be accessible (the pressure

reducing valve has two - only one need be accessible).

●

Where discharge

pipework is difficult to attain, the local building control officer from the local

council should be sought for advice as this falls under G3 guidelines and is not

down to the manufacturer for unvented systems

●

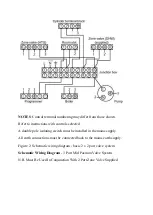

Auxiliary circuit control

●

The 2 port motorised valve supplied with the cylinder MUST be fitted on

the auxiliary flow to the cylinder heat exchanger and wired such that in the

event of the cylinder overheating it will close the auxiliary circuit.

●

Auxiliary

circulation to the cylinder heat exchanger must be pumped; gravity circulation