INST

ALLA

TION

18

Indirect Model

Boiler Selection

The Megaflo Eco SolaReady Indirect models are supplied with an auxiliary heating coil and are suitable for use with most gas

or oil fired boilers compatible with unvented systems i.e. fitted with a temperature control thermostat and thermal cut-out. If

in doubt consult the boiler manufacturer. Solid fuel boilers or any other boiler in which the energy input is not under effective

thermostatic control, unless additional and appropriate safety measures are installed, SHOULD NOT be used. The boiler used

can either be a sealed system or open vented type, maximum primary circuit pressure 0.3Mpa (3 bar). The primary flow

from the boiler MUST be pumped. Gravity circulation will not work due to the special design of the primary heat exchanger.

It is recommended that an air bleed point or automatic air vent is incorporated in the primary return pipework close to the

Megaflo Eco SolaReady unit. The boiler flow temperature should usually be set to 82ºC (maximum flow temperature to

primary heat exchanger 89ºC). The boiler cannot be vented through the Megaflo eco Solar unit.

Indirect Thermal Cut-Out And 2-Port Motorised Valve

To comply with Building Regulations, and to prevent the Megaflo Eco SolaReady from overheating the 2-port motorised valve

supplied MUST be fitted to the primary flow to the indirect coil (see Figure 6).

Wiring

All electrical wiring should be carried out by a competent electrician and be in accordance with the latest I.E.E. Wiring

Regulations.

The Megaflo Eco SolaReady Indirect combined thermostat and thermal cut-out are factory pre-wired. The 2-port motorised

valve supplied MUST be wired in series with the Indirect controls such that the power supply to the valve is interrupted should

either the Thermostat or Thermal cut-out operate. Figure 16, diagrams A, B, D and E detail the wiring required between these

controls and the motorised valve. Wiring to external controls is made via the terminal block fitted. The cable should be routed

through the aperture in the terminal cover and secured using the cable grip provided. The Indirect Thermal cut-out MUST NOT

be bypassed.

Heating System Controls

The controls provided with the Megaflo Eco SolaReady will

ensure the safe operation of the Megaflo Eco SolaReady

within a central heating system. Other controls will be

necessary to control the space heating requirements and

times that the system is required to function. Depending on

the boiler selected, heating circuit design and controls used it

may be beneficial to incorporate a system bypass in the

heating system pipework.

The Megaflo Eco SolaReady is compatible with most heating

controls, examples of electrical circuits are given in the block

wiring schemes. However, other systems may be suitable,

refer to the controls manufacturers’ instructions, supplied

with the controls selected, for alternative system wiring

schemes.

The auxiliary indirect heating source can be controlled via the

Solar Differential Controller – refer to block wiring schemes

B and E and Commissioning Section for setup details.

NOTE: The auxiliary backup immersion heater must have a

separate 13 amp fused supply and cannot be operated via the

Solar Differential Controller on indirect models.

Immersion Heater(s)

The Megaflo Eco SolaReady indirect units (Indirect models) are supplied with an immersion heater which can be used as an

alternative heat source should the boiler supply need to be isolated from the Megaflo Eco SolaReady unit. The immersion

heater is located within the upper controls housing. Refer to page 17 “Wiring and Operation” for details of wiring and

operation of the immersion heater.

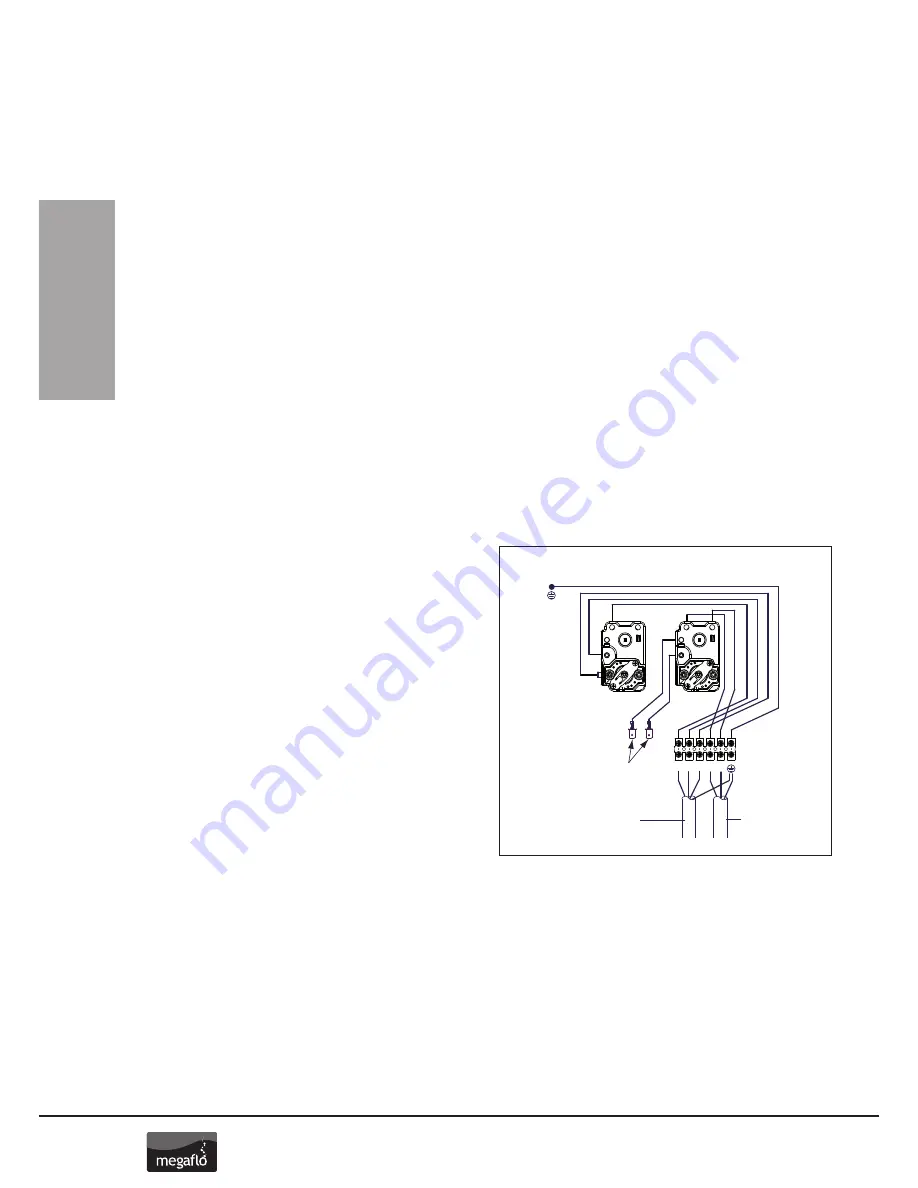

L

N

1 2 3

Control Housing Details

Element Connections

1.5mm² 3 Core

HOFR sheathed

cable

Indirect control

wiring

Figure 15 – Control housing details

Summary of Contents for Eco SolaReady

Page 1: ...Hot Water Cylinders MEGAFLO Eco SolaReady Unvented MEGAFLO Eco SolaReady Product Guide...

Page 48: ...SERVICING 48...

Page 50: ...SERVICING 50...

Page 51: ...SERVICING 51 Notes...