M

AINTENANCE

38

Check solar heat transfer fluid

The heat transfer fluid must be checked every year with regard to its antifreeze and pH value. (7.0 - 9.5) – Check antifreeze

using antifreeze tester. Target value is approximately -21 deg C (40% concentration). Replace fluid if necessary.

Maintenance of the collector

The collector or the collector array must be checked/serviced annually to check for any damage, leaks or contamination.

In areas where there may be a build up of dirt on the collector, only non-abrasive cleaning materials and methods should be

used to clean the collectors and mounting system components.

Benchmark™

On completion of any maintenance or service of the Megaflo Eco SolaReady, the Benchmark™ “Installation, Commissioning

and Service Record” should be filled in to record the actions taken and the date the work was undertaken (page 50).

Fault finding

The Fault finding flow diagrams (Fig 32) will enable operational faults to be identified and their possible causes rectified.

Any work carried out on the Megaflo Eco SolaReady unvented water heater and its associated controls MUST be carried out

by a competent installer for unvented water heating systems. In case of doubt contact the Megaflo Eco SolaReady Service

Department.

Fault finding

Solar differential temperature controller error messages

1. Some system failure modes can be recognised by the solar differential temperature controller and will be indicated by an

error message on the controller display. Refer to the table below for details of possible errors and suggested measures to

rectify.

NOTE: These error messages wil automatically reset when the fault has been rectified. In the case of the circulation error this

may take a few minutes to clear once normal flow has resumed.

42

© Baxi Heating UK 2012

14.0

Fault finding

14.1

Failures with error message

1. Some system failure modes can be recognised by the solar

differential temperature controller and will be indicated by an

error message on the controller display. Refer to the table

below for details of possible errors and suggested measures to

rectify.

NOTE:

These error messages wil automatically reset when

the fault has been rectified. In the case of the circulation error

this may take a few minutes to clear once normal flow has

resumed.

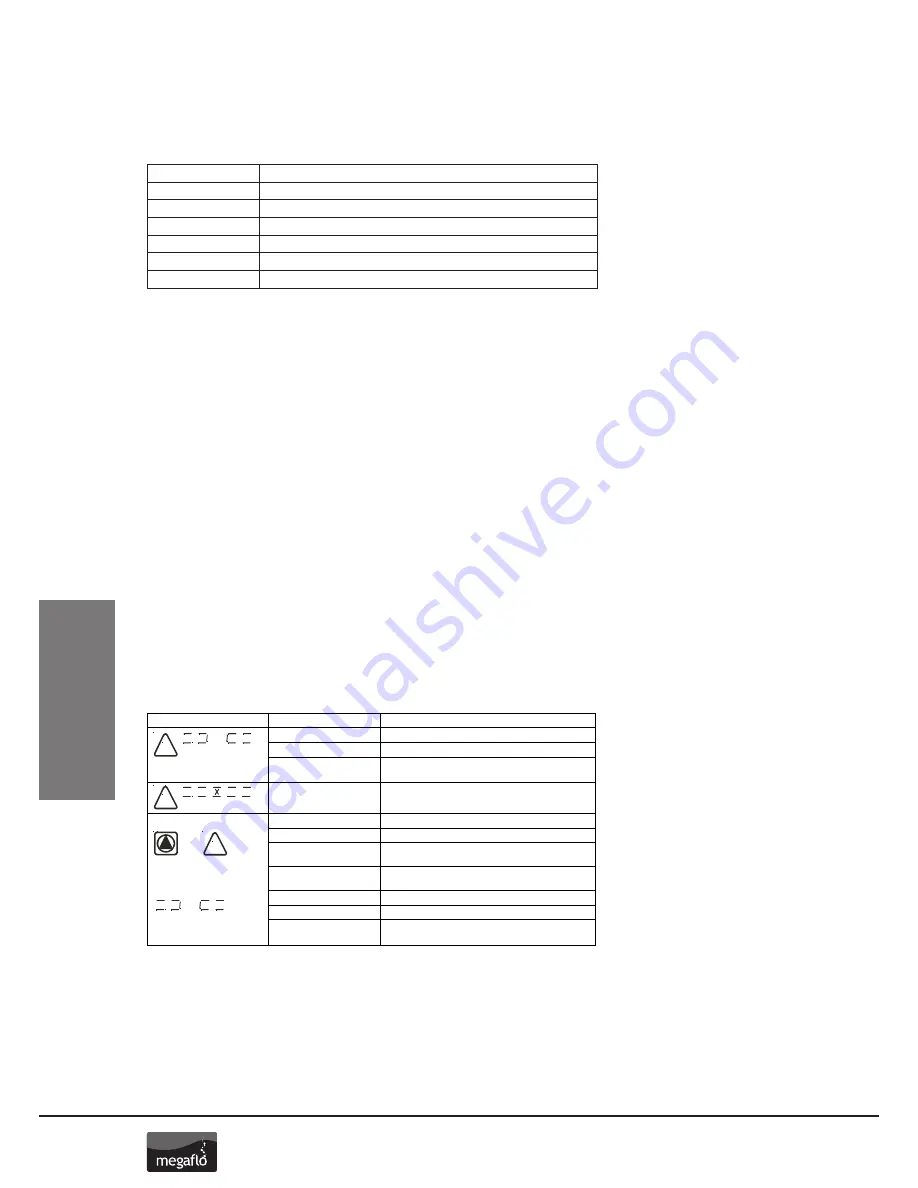

Error representation on display Possible reasons

Measures

• Sensor wire broken

• Check wire

• Sensor defect

• Check sensor resistance, if necessary exchange sensor

• Sensor missing

• Check parameter settings and sensor installation

requirements

• Short circuit in sensor wire

• Check wire

• Sensor defect

• Check sensor resistance, if necessary exchange sensor

• Error in pump connection

• Check cabling

• Pump defect

• Exchange pump

• Air in the system

• Check the float of the flow meter moves

when the system runs (if visible)

• Connection with flow

• Check wire

meter defect

• Sensor wire broken

• Check wire

• Sensor defect

• Check sensor resistance, if necessary exchange sensor

• Sensor missing

• Check parameter settings and sensor installation

requirements

!

!

!

+

Circulation error: no flow

Additionally at energy

productivity measurement:

flashing

flashing

flashing

% volume

Density at 20ºC g/cu.cm

Refractive Index nD20

Frost protection ºC

25

1.023

1.3627

-10

30

1.029

1.3690

-14

35

1.033

1.3747

-17

40

1.037

1.3801

-21

45

1.042

1.3855

-26

50

1.045

1.3910

-32

Summary of Contents for Eco SolaReady

Page 1: ...Hot Water Cylinders MEGAFLO Eco SolaReady Unvented MEGAFLO Eco SolaReady Product Guide...

Page 48: ...SERVICING 48...

Page 50: ...SERVICING 50...

Page 51: ...SERVICING 51 Notes...