22

CARE AND MAINTENANCE

Stainless Steel

There are many stainless steel cleaners available. Always use the mildest cleaning process first,

scrubbing in the direction of the grain. Do not use steel wool as it will scratch the surface. To touch up

noticeable scratches in the stainless steel, sand very lightly with dry 100 grit sand paper in the direction of

the grain.

Grease specks can gather and bake onto the surfaces of the stainless steel, giving the appearance of rust.

For removal, use an abrasive pad with a stainless steel cleaner.

Cooking Grates

The easiest way to clean the grill is immediately after cooking is completed and the flames have been

turned off.

Wear a barbeque mitt to protect your hand from heat and steam.

Scrub the hot cooking grates by dipping a bristled barbeque brush in tap water. Cleaning will be more

difficult if the grill is allowed to cool.

Grease Pan

The grease pan should be emptied, wiped down and washed after each use with a mild detergent and

warm water solution. Check the grease pan frequently and do not allow excess grease to accumulate and

flow out of the grease pan.

Grill Burners

Extreme care should be taken when removing a burner. It must be correctly centered on the orifice

before any attempt is made to relight the grill. Frequency of cleaning will depend on how often you use

the grill.

Failure to properly place the burner over the orifice could cause a fire to occur behind and beneath the

valve panel, thereby damaging the grill and making it unsafe to operate.

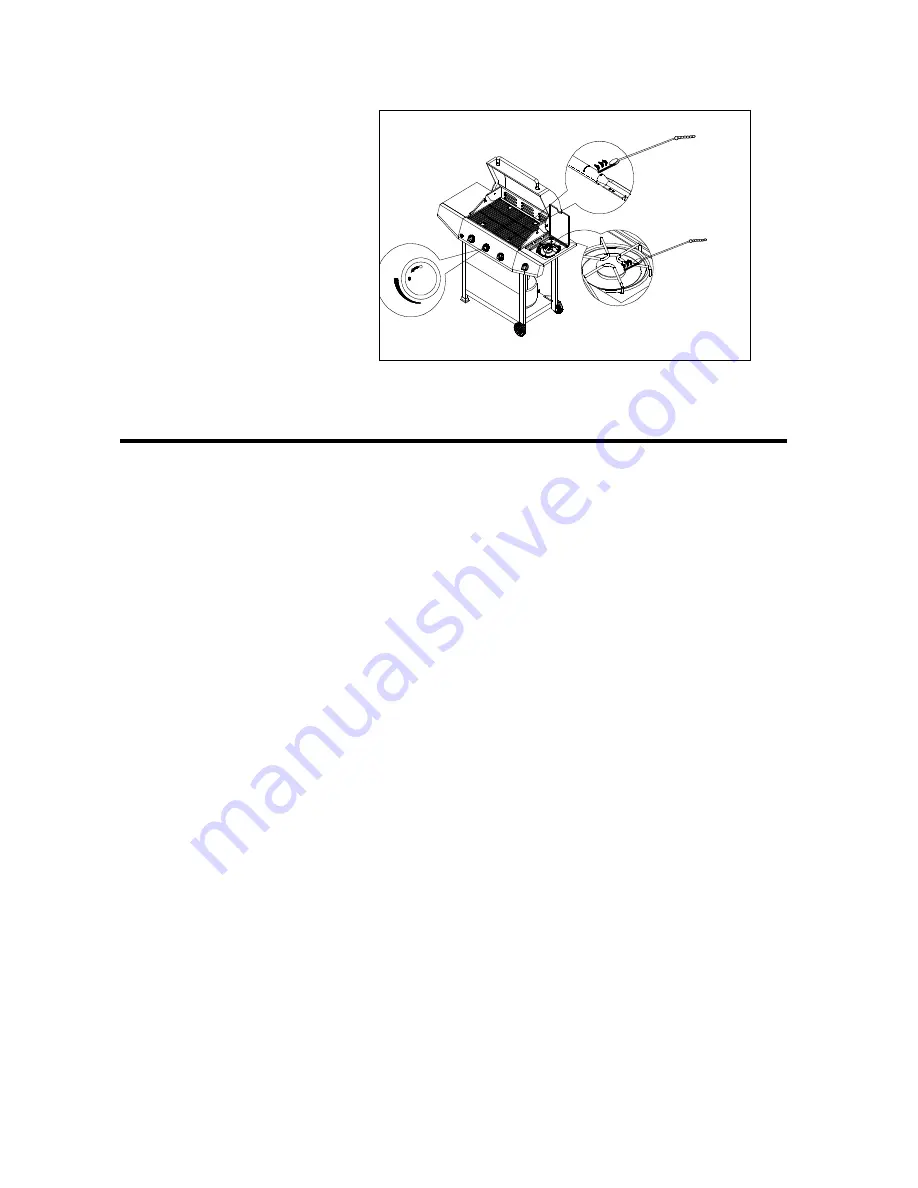

Before cleaning, make sure the gas supply and control knobs are in the

“

OFF

”

position and the burners

have cooled.

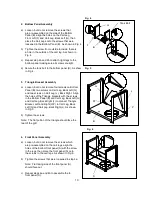

To remove the main burners for cleaning:

1. Locate the burner screw at the rear of the firebox.

2. Remove the screw and lift the burner out of the firebox.

Fig. 23

OFF

LOW

IGNITE

/ HIGH