11

MAINTENANCE

WARNING! INCOMPLETE CLEANING COULD CAUSE FUNCTION FAILURES AND A DEGRADATION OF

THE FAN FORM.

1.

Remove any remaining paint by pouring it into another container.

2.

Disassemble the spray gun making sure to remove the needle before disassembling the nozzle to avoid

damage to the housing of the nozzle closure.

3.

Clean all the paint passages and the nozzle. Clean the other components using a brush soaked in solvent.

4.

Reassemble the spray gun and spray a small quantity of solvent to eliminate all the residues in the paint

passages.

WARNING! NEVER USE METAL OR OTHER OBJECTS THAT COULD DAMAGE THE HOLES IN THE

NOZZLE AND CAP. NEVER IMMERSE THE SPRAY GUN COMPLETELY IN SOLVENT. NEVER USE

COMPONENTS OR PARTS THAT ARE NOT MANUFACTURER ORIGINALS.

Storing

-

When not using spray gun, turn the fluid adjustment knob counter-clockwise to open which will reduce

spring tension on needle fluid tip.

-

Spray gun

MUST BE

well cleaned and lightly lubricated.

TROUBLESHOOTING

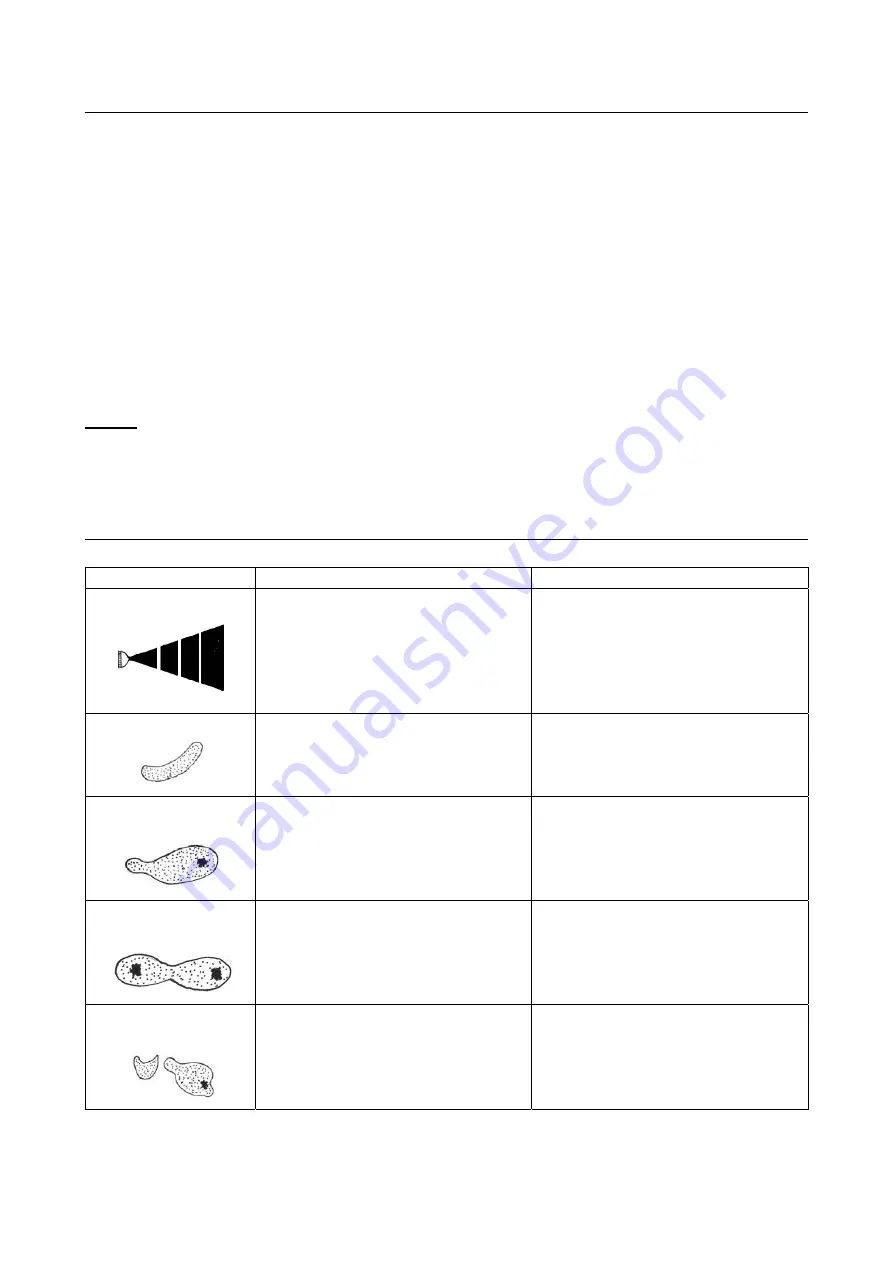

Problem Cause

Solution

Fluttering or spitting

1.

Material level too low.

2.

Container tipped too far.

3.

Loose fluid inlet connection.

4.

Loose or damaged fluid tip/seat.

5.

Dry or loose fluid needle packing nut.

6. Air vent clogged.

1.

Add material into container.

2.

Hold more upright.

3.

Tighten.

4.

Adjust or replace.

5.

Lubricate and/or tighten.

6. Clear vent hole.

Pattern is arc

1.

Worn or loose fluid nozzle.

2.

Material build up on air cap.

1.

Tighten or replace fluid nozzle.

2.

Remove obstructions from holes, but

don’t use metal objects to clean it.

Pattern is not evenly

spread

1.

Material build up on air cap.

2.

Fluid nozzle dirty or worn.

1.

Clean or replace air cap.

2.

Clean or replace fluid nozzle.

The center of pattern

too narrow

1.

Material too thin or not enough.

2.

Atomization air pressure too high.

1.

Regulate material viscosity.

2.

Reduce air pressure.

Pattern width of fan-

sharp is not enough

1.

Material too thick.

2.

Atomization air pressure too low.

1.

Regulate material viscosity.

2.

Increase air pressure.