28

調節裝置

6. Adjustments

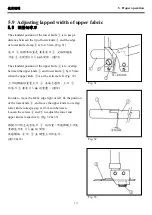

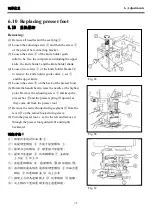

Front-and-rear position of looper and needle:

When the looper

①

moves from the left to the right, it

passes behind the needle.

Adjust the position to make the looper come close to

the needle with the clearance of 0 mm but without

touching when the looper tip comes at the center of

the left needle.

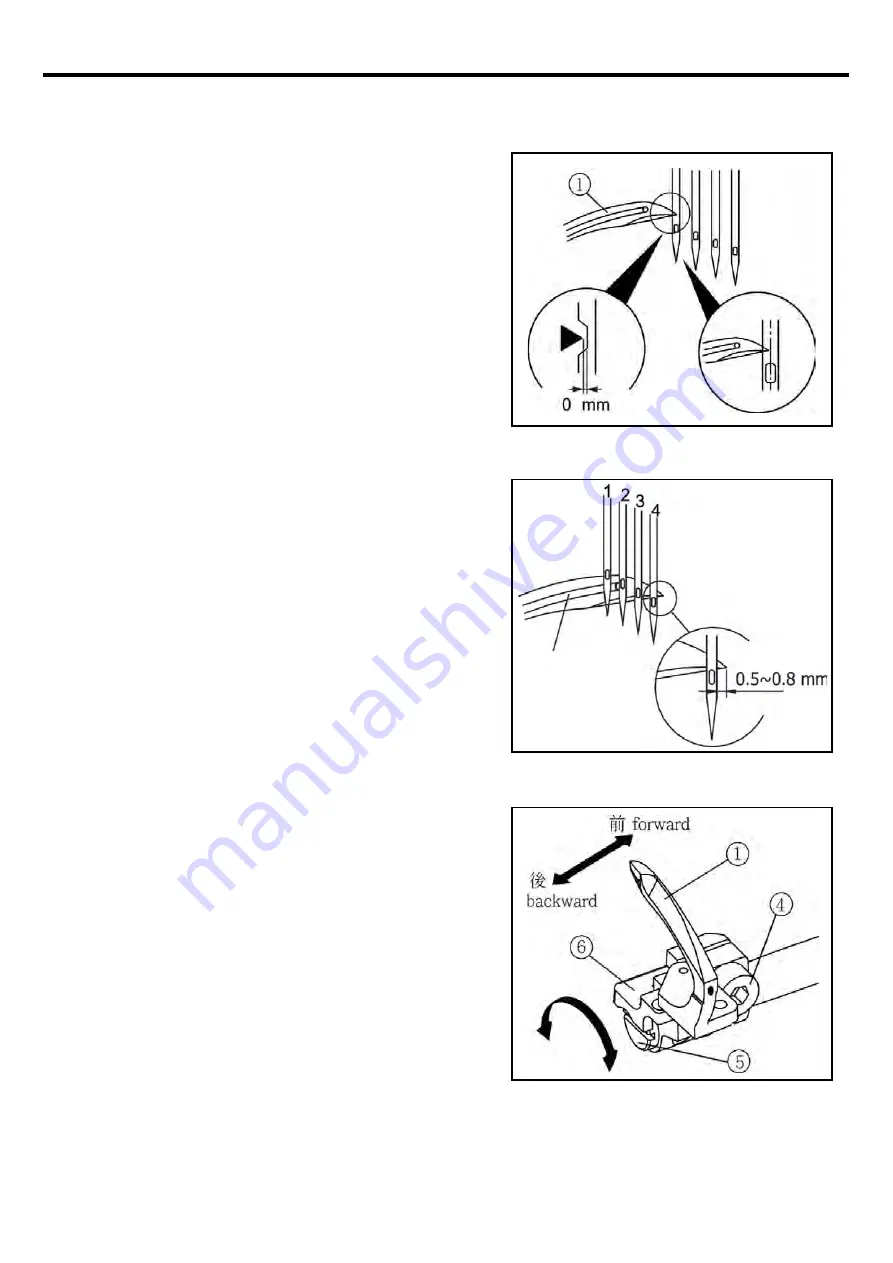

Loosen the screw

④

and turn the adjusting screw

⑤

to adjust it.

●

To move forward, turn the screw

⑤

clockwise.

●

To move backward, turn the screw

⑤

counterclock-

wise. After adjusting, check the distance and tighten

Fig. 49

the screw

④

securely.

下勾針的前後位置:

當下勾針

①

移動從左到右會在針的後面。調整

其位置使下勾針更接近針間隙 0 mm,但不能碰

到針,當下勾針的尖端在左針的中間時,放鬆

螺絲

④

轉動螺絲

⑤

調整前後位置。

● 順時間旋轉螺絲

⑤

會往前。

● 逆時間旋轉螺絲

⑤

會往後。

調整之後檢查間隙和鎖緊螺絲

④

。

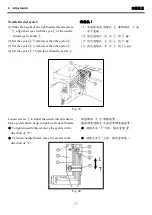

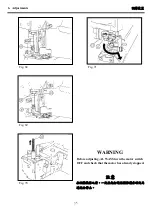

When Looper

①

moves to the right side to the 4

th

Fig. 50

Needle, the bottom edge of the Looper will align

with the upper edge of the 4th Needle hole. At this

moment, make sure the Looper tip passes over the

4

th

Needle by 0.5~0.8mm.

當勾針

①

往右移動至第四根針時,當勾針下沿

對齊針孔上沿時,勾針尖露出第四針 0.5~0.8mm。

Fig. 51

Summary of Contents for MJ101TX

Page 1: ......

Page 4: ...1 1 Name of each part Fig 1...

Page 5: ...2 2 Installation 2 1 Installation 2 1 2 1 1 Tabletop type 2 1 1 Fig 2...

Page 45: ......