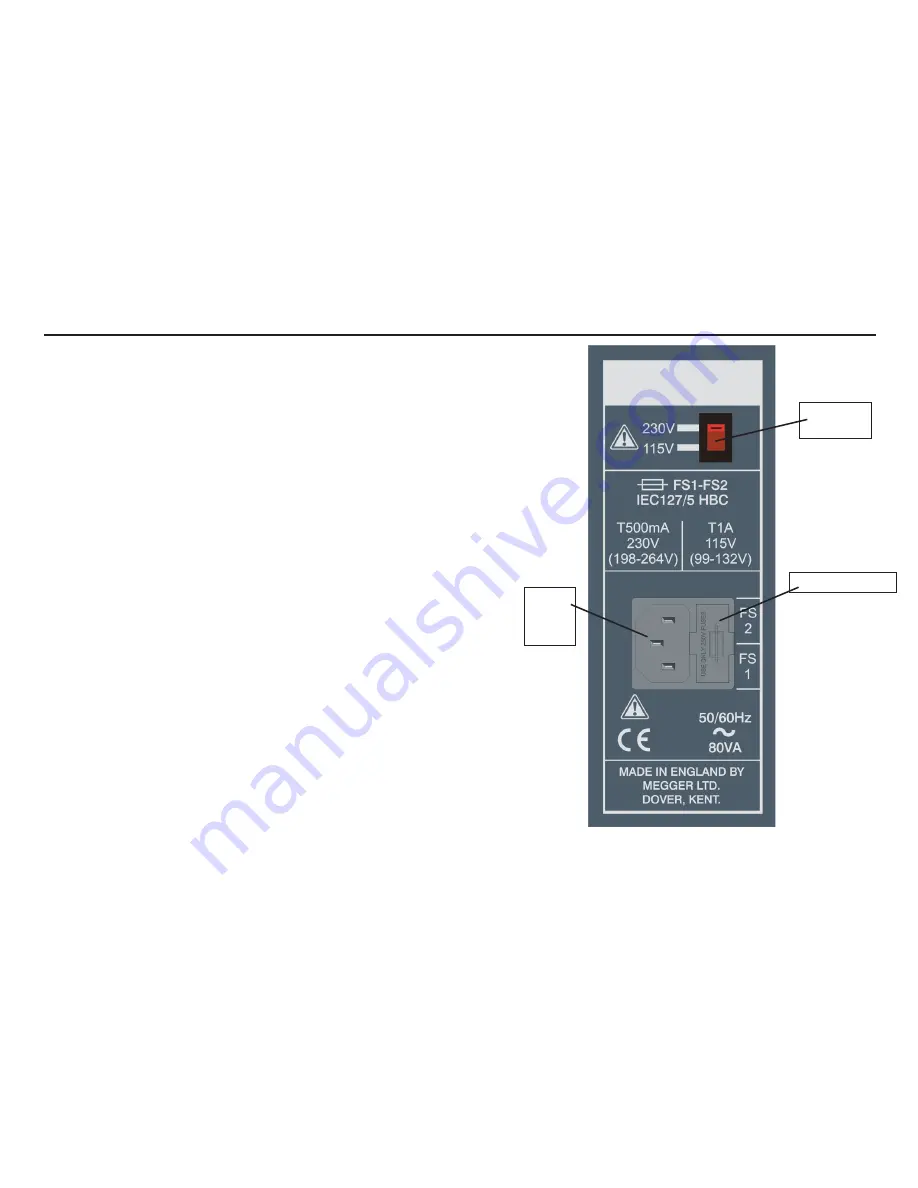

Mains Input Panel

General Description

4.

The

OTS60SX/2

is a lightweight, semi-automatic, oil dielectric strength test set. The

instrument is suitable for protected field use and can be powered from a range of

mains supplies. The maximum 60 kV output allows tests to be performed on oil from

a wide variety of electrical installations including transformers, circuit breakers and

other equipment. The operation of the test set is extremely simple and the results are

displayed on a bright LED display. A selection of vessels enables the instrument to be

configured for a variety of tests.

The semi automatic operation allows all types of testing to be performed. An

automatic one minute timer operates when the high voltage is paused for Withstand

(proof) testing. Oil samples can also be tested according to breakdown specification

by using a suitable sequence of tests.

The instrument is constructed in a strong, sheet steel case. Handles are provided for

ease of transportation. A pouch is located on the side of the instrument to contain

accessories such as the power cord, additional electrodes and the spacing gauge. An

optional carrying case incorporates a shoulder strap.

A number of vessels are available suitable for testing to a wide range of national

specifications. Three types of electrode are available; spherical (IEC type), mushroom

(VDE/ASTM D1816) and cylindrical (ASTM D877). The oil sample can be stirred by a

motor driven impeller available in selected vessels. The vessel is located in the top of

the instrument and covered by a transparent polycarbonate door with a mesh screen

so that the oil breakdown can be viewed. A safety interlock ensures that the high

voltage is disconnected when the chamber door is opened.

Voltage

Selector

Mains

power

input

Fuseholders