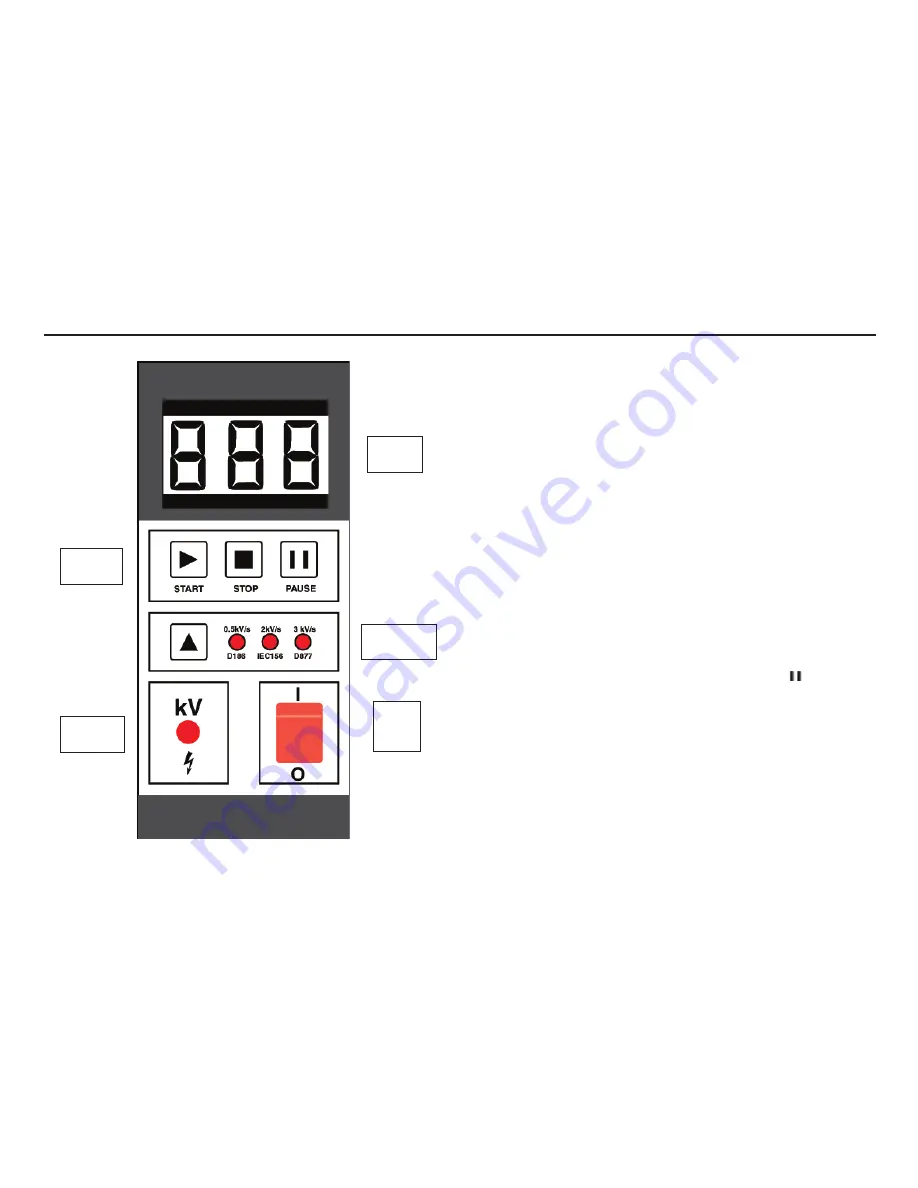

Control Panel

The control panel contains the supply on/off switch, the high voltage display, voltage

ramp rate selection and the three control keys. The operation of the instrument is

very simple. When the instrument is turned on, the on/off switch is illuminated, and

the software edition code will be flashed up on the display.

Breakdown Testing

The suitable ramp rate for the test to be performed should be selected using the ‘

s

’

key. The

START

key ‘ ‘ will then turn on the high voltage. The red H.V. indicator

will light to show the output voltage is on. The voltage will then increase at the

selected ramp rate and the corresponding value will be shown on the display. If oil

breakdown occurs the instrument will detect this and immediately shut off the high

voltage. The breakdown voltage value will be left on the display until the next test is

started. If no breakdown occurs, the high voltage will rise to

60 kV. At this point the test voltage is cut off and this maximum value left on the

display.

A test can be stopped at any time by pressing the

STOP

‘

■

’ button. This will remove

the high voltage from the oil sample and leave the display at

0,0 kV

.

Withstand Testing

A Withstand (proof) test can be carried out by pressing the

PAUSE

‘ ‘ key. This will

maintain the high voltage at the current value for one minute. After this time the

high voltage will continue to rise until one of the following:-

1) Oil breakdown occurs

2) The

STOP

‘

■

’ key is pressed

3) The output voltage reaches the maximum value of the test set.

During withstand testing the ramp rate can be changed while the pause is in

progress. This can allow the withstand test value to be accurately set by adjusting the

ramp rate to the lowest value.

6.

Mains

on/off

switch

HV on

indicator

Ramp rate

selection

Main

controls

LED

Display

Control Panel

s