7

Warning Messages

Door Open

If the instrument overheats, the words ‘

‘ and ‘

‘ will be

alternately displayed and the operation disabled. This will reset automatically, when

cooled, after a few minutes.

Testing to National Standards

The

OTS60SX/2

can be used to test to any international standard. A table of the

standards is given on page 10. To perform these tests it is necessary to select the

correct vessel so that the specified electrodes and suitable stirring are used. Most

standards require repetitive breakdown tests to be carried out and the average taken.

Note that sometimes the first breakdown result is omitted from the average calculation.

If continuous stirring is not required the stirrer motor supply can be disconnected when

appropriate by opening the chamber door.

100 ml Oil Test Vessel

The D877 Low Volume Test Vessel is an optional accessory for use with the Megger®

OTS60SX/2

Oil Test Set.

The test vessel must be kept scrupulously clean. Before each use, dismantle the test

vessel, clean and dry, re-assemble, and set the electrode gap to 2,54 mm (0.100 inch).

Dismantling the vessel

1.

Loosen both white locking screws.

2.

Hold each electrode in turn, and unscrew, and remove the sliding arm from

each electrode.

3.

Remove both electrodes from the vessel.

4.

Wash hands, and clean and dry the vessel as specified in ASTM D.877.

Re-assembling the vessel

1.

With clean, uncontaminated hands, place the cleaned electrodes in the

vessel.

2.

Position each electrode in turn with the fingers, and screw in a sliding arm

through the vessel into the each electrode in turn.

3.

Centre the electrodes, and set the gap, using the appropriate gauge.

4.

Ensuring that the Viton ‘O’ rings are not fouled, hand tighten both locking

screws.

Megger Limited

also supply a range of automatic oil test sets. These have the

parameters of a wide range of specifications programmed into the instrument for

unattended operation.

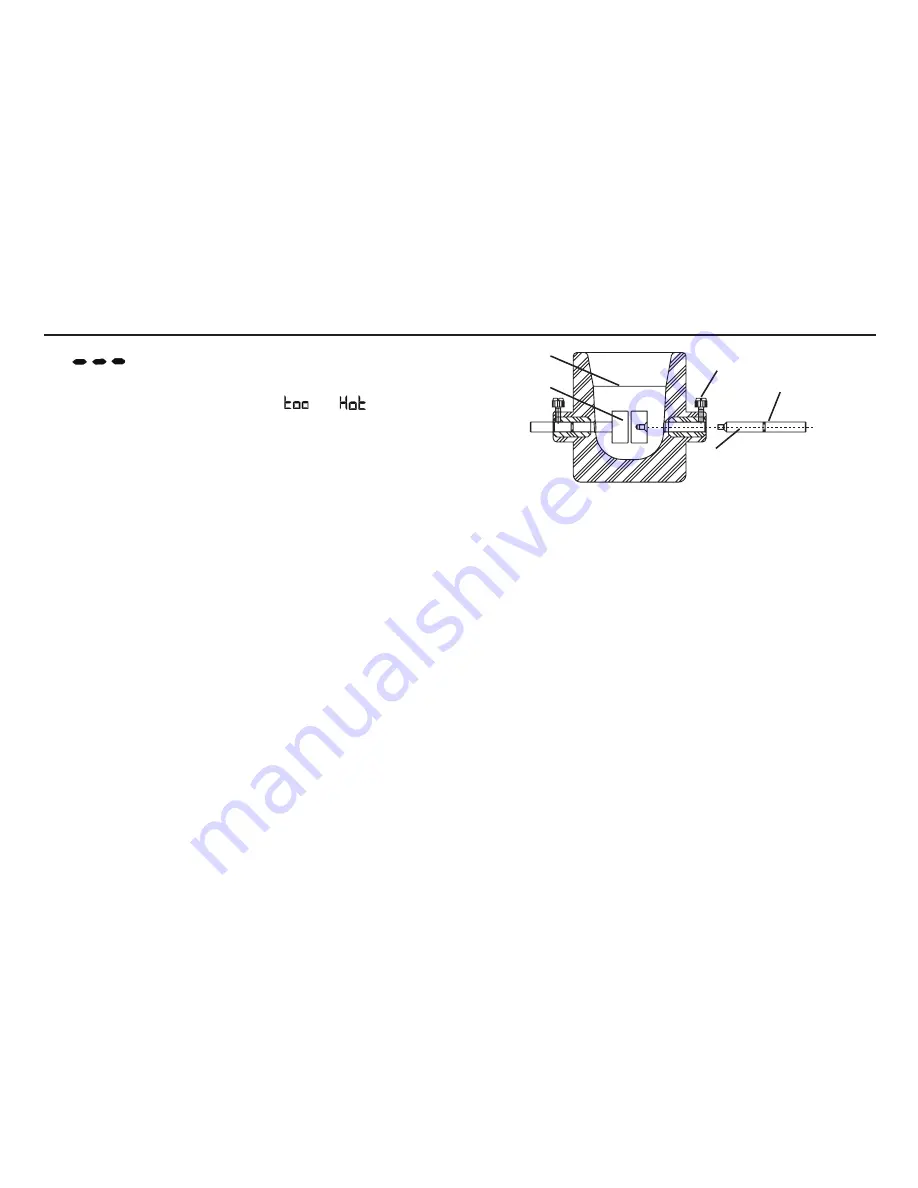

Electrode

Viton

(Oil resistant)

‘O’ Ring

Locking

screw

Sliding arm

Fill level