Warnings

1. The test set is only to be used by a suitably trained and competent person who is familiar with current

injection testing and who is aware of the hazards involved in working with heavy current equipment.

2. Ensure that the test set is properly earthed before use, either through the mains supply cable or

through the separate green/yellow wing-nut terminal on the terminal panel.

3. Ensure that all output terminals and the test leads used are free from dirt and grease prior to switching

the test set on.

4. Be aware that the PCITS600/2 and PCITS2000/2 are capable of hazardous outputs in excess of 50 V,

therefore do not touch the terminals, connectors or the equipment under test while the power is

switched on.

DO NOT CONNECT MAIN CURRENT OR AUXILIARY VOLTAGE TERMINALS TO A LIVE

POTENTIAL.

5. The flow of heavy current from the test set through the circuit under test will inevitably produce heat. Be

aware that the metal parts of terminals and lead connectors may be quite hot when touched. This is

unlikely to be the case however, unless the set is used at high output currents for long periods.

6. Only correctly rated output test cables must be used. Suitable leads are available optionally; 600 A

rating for the PCITS600/2 and 2000 A rating for the PCITS2000/2. Do not make connections to the

auxiliary voltage terminals when connections to the current terminal are already made, and vice

versa.

7. Do not exceed the permitted duty cycle of the test set, as defined in the Specification section.

8. Ensure that the correct power supply voltage is used and that the supply cable is terminated by a

suitable plug. The supply capacity must be sufficient to maintain the supply voltage within range at the

full output of the test set.

9. Use a supply socket that is provided with a protective earth contact. Do not use an extension cable

without a protective conductor. (Ensure that any extension cable is adequately rated).

10. Do not open the casing of the test set while it is connected to the supply.

11. It is important that replacement fuses are of the correct type and rating.

12. Whenever it is likely that the protection has been impaired, the test set must not be used but returned to

the manufacturer or his approved agent for repair. The protection is likely to be impaired if, for example,

the test set shows visible damage, fails to perform the intended measurements, has been subjected to

prolonged storage under unfavourable conditions or has been subjected to severe transport stresses.

Precautions

1. Any servicing or repair must be carried out by the manufacturer, otherwise any warranty covering the

test set may be invalidated.

2. The instrument contains static sensitive devices. If the instrument is opened for any reason (this will

automatically invalidate any warranty covering the equipment unless carried out by the manufacturer)

care must be exercised in handling the printed circuit boards. This should be done in accordance with

DEF STAN 59-98 and BS 5873, specifications for handling electrostatic sensitive devices.

3. If, after prolonged use, the test set appears faulty and fails to produce the required output current or

voltage, it may be that the variac’s wiped track needs cleaning. Consult the manufacturer or one of his

approved agents for advice on this.

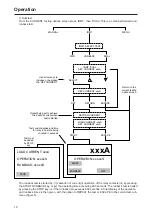

Operation

10

Summary of Contents for PCITS2000/2

Page 1: ...M PCITS600 2 PCITS2000 2 Primary Current Injection Test Sets User Guide Benutzerhandbuch...

Page 5: ...5 Figure 1 PCITS600 2 and PCITS2000 2...

Page 23: ...23...

Page 37: ...37...

Page 38: ...38...