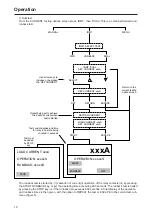

Other Messages

During operation events might occur which prohibit the normal operation of the test set. When this happens

the display screen will show ‘SYSTEM ERROR’ and a message to indicate what is causing the the

malfunction A brief Summary of these messages is given below.

‘THERMAL OVERLOAD’

This message is given if the permitted duty cycle has been exceeded and the thermal cut-out has operated.

When the test set has cooled sufficiently the ‘CONTINUE’ key can be pressed to return to the main menu.

‘OPEN CIRCUIT’

If, during a programmed test, the test set does not give any current , then the output is shut off and this

message is given. This can occur due to an open circuit in the item under test, or, a ruptured fuse or a

circuit breaker having operated in the test set.

‘FAILURE TO SET’ and ‘-!-’

The ‘-!-’ symbol appears on the current ranges if the set current is not attained within 36 seconds of the test

commencing. If proper set-up cannot be achieved after a further 55 seconds then a ‘FAILURE TO SET’

warning is issued and the test is aborted.

On the manual current ranges the ‘-!-’ warning is cleared if the test current is corrected in the allowed time.

However the indication remains for the duration of an IDMT test and the subsequent results screen. This

warns the operator that a consistent current was not obtained during the test and a retest might be advisable.

‘RANGE CHANGED’

This appears if the range switch is altered during a test. The test is aborted and the instrument resets to

acknowledge the new range selected.

‘RELAY FAULT’

This appears if an output is detected when the internal solid-state relay is normally off. This is defined as a

hazardous condition and the only instruction, after a complete rewind of the variac, is to ‘DISCONNECT’ the

instrument from the mains supply immediately. If recurrent, the instrument must be returned for servicing.

‘DATA ERROR’

This will appear if an internal data corruption occurs in the microprocessor hardware. To avoid processing

errors, you are instructed to ‘DISCONNECT’ the instrument from the mains supply, and restart operation

over again. Please note that this is a rare fault and really just a precaution to avoid unpredictable operation.

Resetting the instrument should fully restore normal operation. You should seek advice if this condition

frequently occurs.

Operation

18

Summary of Contents for PCITS2000/2

Page 1: ...M PCITS600 2 PCITS2000 2 Primary Current Injection Test Sets User Guide Benutzerhandbuch...

Page 5: ...5 Figure 1 PCITS600 2 and PCITS2000 2...

Page 23: ...23...

Page 37: ...37...

Page 38: ...38...