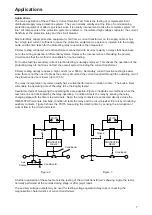

The PCITS600/2 and PCITS2000/2 are mainly intended for use in testing protection relays in electricity

supply installations. Other general uses include current transformer testing.

Each test set provides a variable high current source and an auxiliary voltage source. Both outputs can be

pre-set before a test and remain stable under varying load conditions or varying supply voltages during

operation. The PCITS2000/2 contains a 6 kVA step down transformer and the PCITS600/2 a 2,4 kVA unit.

Both are intermittently rated at maximum output. The loading transformer is fed from a stepper motor

controlled variable transformer. Two ranges are provided by switching the connections of the transformer’s

primary circuit.

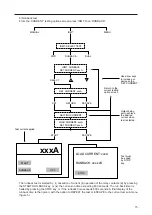

A hand-held controller houses the l.c.d. display and the software defined keys that are used to select the

required current and voltage settings and operate the test set. A built in timer is used to measure the

time/current and runback performance of the relay under test.

The circuit can be considered in three sections:-

The high current circuit

made up of the mains supply input, main switches, variable

transformer and loading transformer.

The power supply p.c.b.

including the high current measurement and d.c. voltage supplies.

The control p.c.b.

which is housed in the controller and contains the microprocessor

and all its associated circuitry.

High Current Circuit

The mains input is directly connected to the power on/off switch. Overcurrent protection is provided by two

circuit breakers in the high current circuit and a 1 A fuse for the low-current power supply. Circuit breaker

CB1, a long delay magnetic device, is used on the input to the variable transformer to safeguard the mains

input. A solid state relay switches the input to this variable transformer and its wiper brush is protected by

circuit breaker CB2, a short delay device, since the brush current can be more that the input current.

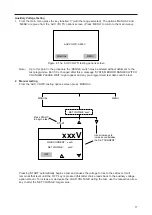

Switch SW2 configures the loading transformer in either series or parallel primary connections to change

the output range of the test set. It has an extra pole which is used to send a signal to the microprocessor

so that the correct range can be indicated on the display. This transformer is a step down transformer with

a large cross section copper secondary. A thermal cut-out is fitted to the secondary to prevent the windings

heating to over 100˚C (PCITS2000/2) or 90˚C (PCITS600/2). This cut-cut will safeguard the primary

insulation. The transformer also has a low current auxiliary winding with a maximum output of 250 V and

protected by a 2 A fuse.

All metal surfaces on the test set are connected to earth and a separate earth terminal is provided.

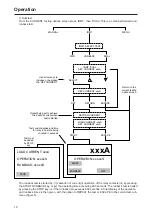

Power Supply Circuit

Several power supply rails are used. These are derived from transformers on the power supply p.c.b. One

transformer provides the 5 V supply for the logic ICs, ±12 V for the analogue ICs and the display contrast,

and an unregulated 12 V supply for the stepper motor and solid-state relay drives. A separate transformer

supplies the isolated contact-sense circuit.

Current Measurement

Current is measured in both the main and auxiliary outputs using a current transformer and an a.c. to d.c.

converter. The current transformer has two windings – a 333 turn (PCITS2000/2) or 100 turn

(PCITS600/2) auxiliary winding and a 4000 turn (PCITS2000/2) or 1200 turn (PCITS600/2) drive coil.

Isolated Contact Sensor

This determines the status of the contacts of the relay under test and allows them to float above the earth

potential. Isolation is provided by the separate supply transformer and a relay unit. A rectified a.c. voltage

appears at the timer sockets to break through any contamination on the contacts. The circuit can detect

changes in both volt-free and 100 V-264 V a.c./d.c. energised contacts.

Stepper Motor Drive

The step per motor which controls the variable transformer is driven by a Darlington driver IC on the power

supply p.c.b. A constant current supply is used by this IC to maintain reliable operation across a range of

mains supply voltages. The spikes produced by the stepper motor changing state are reduced by a

capacitor.

Circuit Description

21

Summary of Contents for PCITS2000/2

Page 1: ...M PCITS600 2 PCITS2000 2 Primary Current Injection Test Sets User Guide Benutzerhandbuch...

Page 5: ...5 Figure 1 PCITS600 2 and PCITS2000 2...

Page 23: ...23...

Page 37: ...37...

Page 38: ...38...