Applications

The main application of these Primary Current Injection Test Sets is the testing of complete electrical

distribution/supply relay protection systems. They are normally employed at the time of commissioning

protection equipment or after major repair since it is usually inconvenient to take the complete system “off

line”. All components of the protection system are tested i.e. the isolated high voltage conductor, the current

transformer, the protection relay and the circuit breaker.

Most electricity supply protective equipment is fed from a current transformer on the supply cable or bus

bar. A high test current, sufficient to cause the protection equipment to operate, is injected into the supply

cable and the time taken for the protecting relay to operate is then measured.

Primary testing will detect current transformers connected with incorrect polarity or relays that have been

set in the wrong sequence in differential systems. However the inconvenience of breaking the primary

circuit means that the method is unsuitable for routine testing.

For routine testing secondary current injection testing is usually employed. This checks the operation of the

protecting relay etc. but does not test the overall system including the current transformer.

Primary testing usually requires a high current (over 500 A). Secondary current injection testing is easier

since there is not the need to break the primary circuit and the current required through the operating coil of

the protective device is lower (up to 100 A).

The relay incorporated in systems usually has a critical performance in relation to time. The built-in timer

will enable the operating time of the relay to be thoroughly tested.

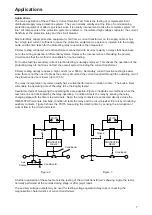

Several methods of measuring the operating time are possible. Figure 2 illustrates two methods when the

test current is not interrupted by the relay operating. Condition A tests the relay by sensing the relay

changing state with the timer stop terminals. Note: the relay contacts are connected directly across the

TIMER-STOP terminals. Similarly, condition B tests the relay and the circuit breaker trip coil by monitoring

auxiliary contacts. Figure 3 shows the PCITS measuring the total trip time by sensing the interruption of

current flow in the circuit under test.

A further application of these test sets is the testing of the current transformer’s phasing. Again the test is

normally performed at the commissioning stage or after major repair.

The auxiliary voltage outputs may be used for testing voltage operated relay coils or checking the

magnetization characteristics of current transformers.

Applications

7

–

+

X

PCITS

PROTECTIVE

RELAY

Condition A

Condition B

Aux

Contact

–

+

X

PCITS

PROTECTIVE

RELAY

Condition C

Closed

Figure 2

Figure 3

Summary of Contents for PCITS2000/2

Page 1: ...M PCITS600 2 PCITS2000 2 Primary Current Injection Test Sets User Guide Benutzerhandbuch...

Page 5: ...5 Figure 1 PCITS600 2 and PCITS2000 2...

Page 23: ...23...

Page 37: ...37...

Page 38: ...38...