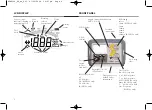

LED indicators

Three RED led indicators show circuit connection status when correctly

connected to a live circuit. These are for indication purposes only and

should not be relied upon as a indication of the presence of a hazardous

voltage.

When connected to the circuit to be tested the three status LED’s will

show the following supply connection information:

LED Normal

Reversed

Notes

Indicator Supply

(L-N) supply

=ON = OFF

L - PE

Voltage between L- PE

greater than 25 V

L - N

Voltage between L-N

greater than 25 V

N - PE

Voltage between N-PE

greater than 25 V

Warning:

Voltage indicator LED’s cannot reveal a N-PE supply reversal

Polarity Indication

If connected to a single phase power supply by a plug or by the 3-wire

lead set, three LED’s marked L-PE, N-PE and L-N respectively will

indicate supply polarity

NOTE:

The presence of a voltage between phase and earth does not

prove earth continuity, as the earth could have a high resistance and a

voltage would still be measured. To test earth continuity refers to the

sections on loop testing.

RESIDUAL CURRENT DEVICE [RCD] TESTING

11

Method of measurement

The plug ended test lead or two wire lead should be used for this

measurement. A constant current source is connected across the supply

and the time taken for the supply to trip is measured by the instrument

in milliseconds (ms).

The RCDT310 and RCDT320 can perform the following RCD tests:

Type

The RCD type is selectable from, AC, AC Selective, DC, DC

Selective, depending on instrument.

1/2I

Non-tripping test at half the rated RCD trip current for 2

seconds, during which the RCD should not trip.

I

Tripping test at the rated RCD trip current started on zero

crossing of the positive half cycle. The trip time will be

displayed

5I

Tripping test at 5 x the rated RCD trip current. The trip time

will be displayed in milliseconds.

0 or 180°

Some RCDs are sensitive to the polarity of the supply, i.e

whether the test current is applied on the instantaneous

rising or falling part of the supply cycle. Tests should

therefore be performed at 0° and 180° and the maximum

time recorded.

Additionally the RCDT320 can perform the following tests:

AUTO

Automatically steps through each RCD test (including 0 or

180°) whilst the operator stands by the RCD to reset it.

RampTest

Used to check the trip current of an RCD.

RCDT300_UG_en_V01 07/05/2004 12:07 pm Page 11