Page 24

Insulation measurements above 100 G

Ω

Measurements up to 100 G

Ω

can be made without any special

precautions, assuming that the test leads are reasonably clean

and dry. The guard lead can be used to remove the effects of

surface leakage if necessary. When measuring resistances above

100 G

Ω

, the test leads should not be allowed to touch each other,

or any other object since this will introduce leakage paths. Sharp

points at the test lead connections should also be avoided since

this will encourage corona discharge.

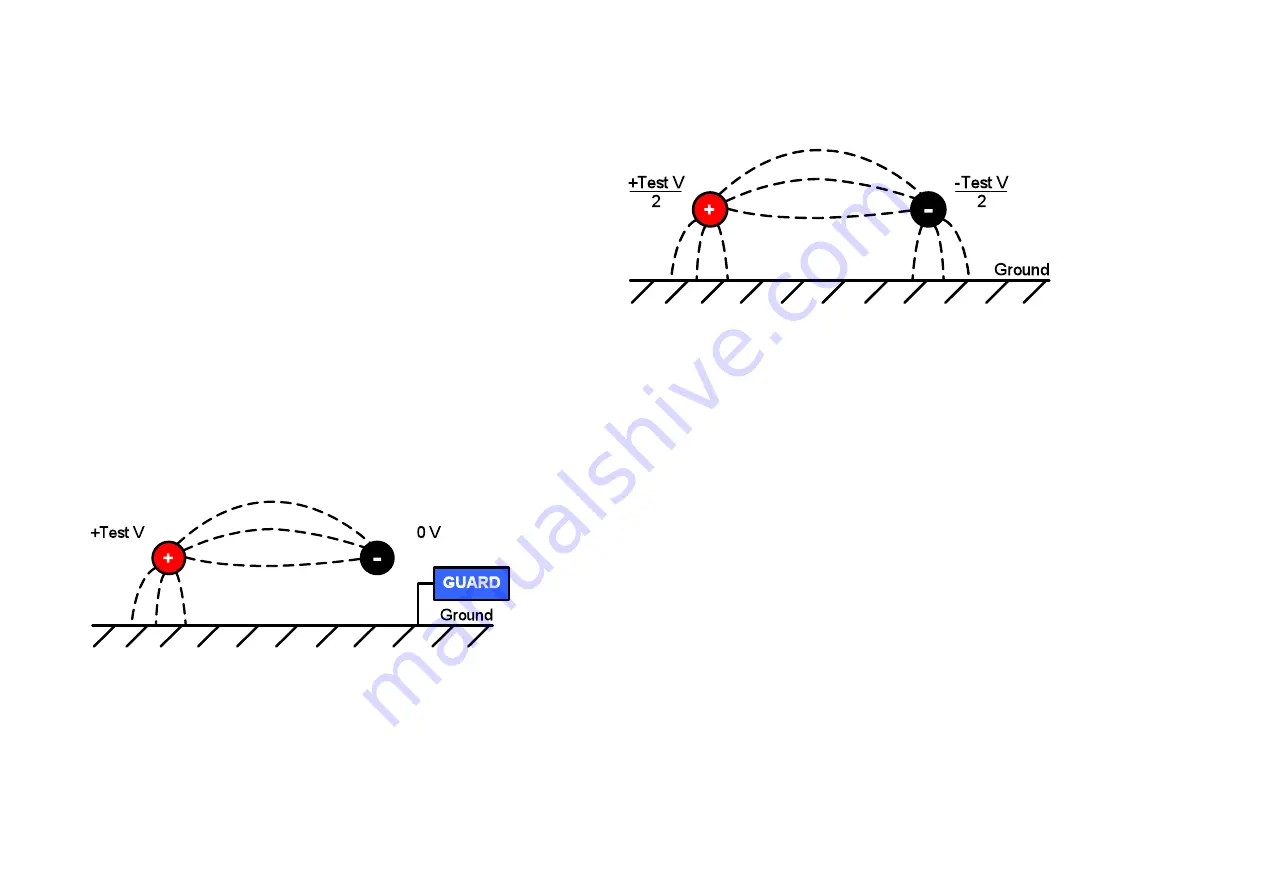

The output is isolated, and so will float relative to ground such

that the positive terminal is at plus half of the test voltage, and the

negative terminal is at minus half of the test voltage with respect

to ground.

Leakages therefore occur between the positive terminal and

ground, between the negative terminal and ground, and directly

between the positive and negative terminals. These leakages

have a significant effect and can occur through air.

If the guard lead is grounded, and since the negative terminal is

at the same voltage as the guard terminal, the leakage into the

negative terminal will be considerably reduced. This will improve

accuracy because the current flowing into the negative terminal is

measured by the instrument and used to calculate resistance.

This technique is only permissible if the item under test is isolated

from ground. In this context

isolated

means insulated by a

resistance of at least 5 M

Ω

for the positive terminal, or at least

10 k

Ω

for the negative terminal.

Conversely, if the positive terminal is grounded, then the negative

terminal will be at a voltage equal to the test voltage relative to

ground, which will result in an increase in leakage current, and

worsening of measurement accuracy.

When making measurements above 100 G

Ω

therefore, the user

should ground the Guard lead where possible otherwise parallel

leakage paths may occur.

Alternatively, screened leads are available as an optional accessory

from Megger. When using a screened lead the screen is plugged

into the Guard terminal, diverting any leakage currents. This

considerably improves measurements made with a floating output,

where the leads might touch each other or another object other than

the test piece.

Terminals

There are three test terminals , - and GUARD. These

terminals are designed to accept only genuine Megger test leads.

Shutters across the terminals prevent accidental ingress of dirt and

other objects. Test lead plugs interlock with the shutters and are

released by rotating the test lead plug by a quarter turn.

The GUARD terminal, as explained below, is only used in cases

where surface leakage currents need to be eliminated. Most