14

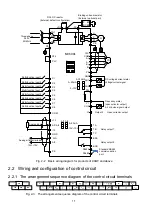

Multi-funct

ional

output

terminal

Y1

Open collector

output terminal

1 / DO pulse

output terminal

It can be set as the digital output

terminal with multiple functions and also

can be reused as DO pulse output

terminal, which is selected by the

function code P09.17. For details,

please refer to the introduction to the

functions of P09.17 or P09.29 in “Digital

input/output parameters” (Group P09)

(common terminal: COM).

Opto-isolated output

Maximum operating voltage: 30V

Maximum output current: 50mA

The DO pulse output frequency range

depends on P09.30 and the maximum

value is 50kHz

Y2

Open collector

output terminal

2

It can be set as the digital output

terminal with multiple functions. For

details, please refer to the introduction

to the functions of P09.18 in “Digital

input/output parameters” (Group P09)

(common terminal: COM).

Opto-isolated output

Maximum operating voltage: 30V

Maximum output current: 50mA

Power

supply

P24

+24V power

supply

To p24V power for external load Maximum output current: 200mA

Common

terminal

PLC

Multi-functional

input common

terminal

Common terminal of Multi-functional

input terminal (Short circuited with P24

upon delivery)

Common terminal of X1~X8, PLC is

interally isolated with P24

COM

+24V power

common

terminal

2 common terminals in total, used

together with other terminals

COM is internally isolated with GND

Relay

output

terminal 1

TA

Relay output

It can be set as the relay output terminal

with multiple functions. For details,

please refer to the introduction to the

functions of output terminals of P09.20

in “Digital input/output parameters”

(Group P09) (common terminal: COM).

TA-TB: Normally closed;

TA-TC: Normally open

Contact capacity:

AC250V/2A

(

COS

Φ

=1

)

AC250V/1A

(

COS

Φ

=0.4

)

DC30V/1A

For operating method, please refer to

the description of P09. The over-voltage

class for the input voltage of the relay

output terminal is class II.

TB

TC

Relay

output

terminal 2

BRA

Relay output

It can be set as the relay output terminal

with multiple functions. For details,

please refer to the introduction to the

functions of output terminals of P09.21

in “Digital input/output parameters”

(Group P09) (common terminal: COM).

BRA-BRC: Normally open

Contact capacity:

AC250V/2A

(

COS

Φ

=1

)

AC250V/1A

(

COS

Φ

=0.4

)

DC30V/1A

For operating method, please refer to

the description of P09. The over-voltage

class for the input voltage of the relay

output terminal is class II.

BRC