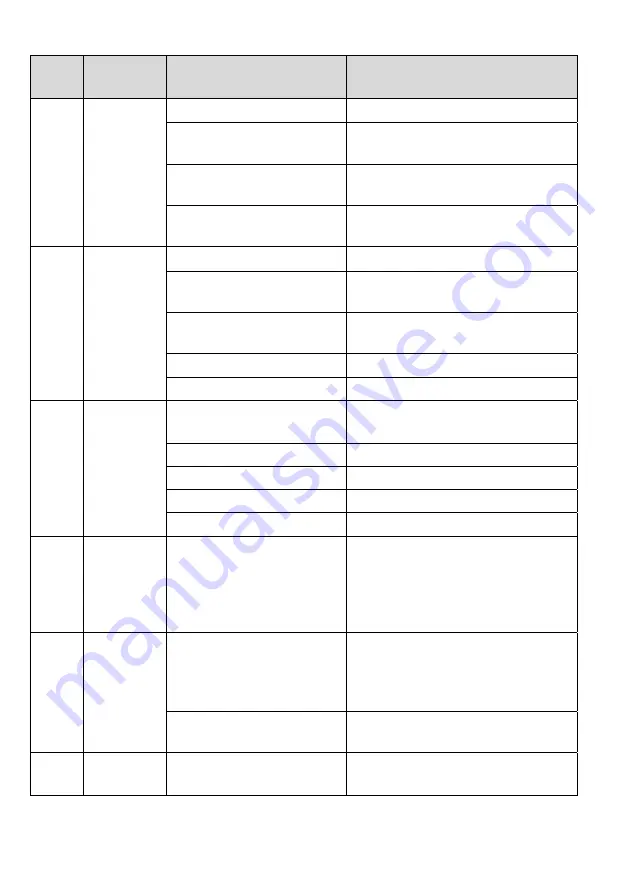

61

Fault

code

Fault type

Possible fault cause

Solutions

Er.SC1

Abnormal remote

serial port

communication

The baud rate is set improperly.

Set the baud rate properly.

Serial port communication error

Reset by pressing the STOP/RESET key, seek for

service support

The fault alarm parameters are set

improperly.

Modify the P15.03 and P97.00 settings

The host device does not work.

Check if the host device is working and if the wiring

is correct.

Er.rLy

Abnormal

contactor

The grid voltage is too low.

Check the grid voltage

The contactor is damaged.

Replace the contactor of the main circuit, seek for

service support

The power-up buffer resistance is

damaged.

Replace the buffer resistance, seek for service

support

The control circuit is damaged.

Seek for service support

Input phase loss

Check the input R.S.T. wiring

Er.CUr

Current detection

circuit abnormal

The wirings or the plug-in units of the

control board loosens.

Check them and rewiring

The auxiliary power supply is damaged. Seek for service support

The Hall device is damaged.

Seek for service support

The amplifying circuit is abnormal.

Seek for service support

The AI analog input voltage is too high.

Reduce the AI analog input voltage to less than 12V

Er. EGL

External

reference

command lost

During the frequency main reference or

the torque command selection analog

current reference, the analog reference

signal is disconnected or too low (less

than 2mA).

Check the wiring or adjust the input type of the

reference signal

Er.CoP

Operation panel

parameter

copying error

The operation panel parameters are

incomplete or the operation panel

version is inconsistent with main control

panel version.

Refresh the operation panel data and version, use

P00.06=1 for uploading the parameters first and

then use P00.06=2 or 3 for downloading.

The operation panel EEPROM is

damaged.

Seek for service support

Er.TUn Poor

auto-tuning

The nameplate parameters of the motor

are incorrect.

Set the parameters properly according to the motor

nameplate