MeiG

Product

Manual

of

SLM750

Module

SLM750

Module

Hardware

Design

Page 34, total 84 pages

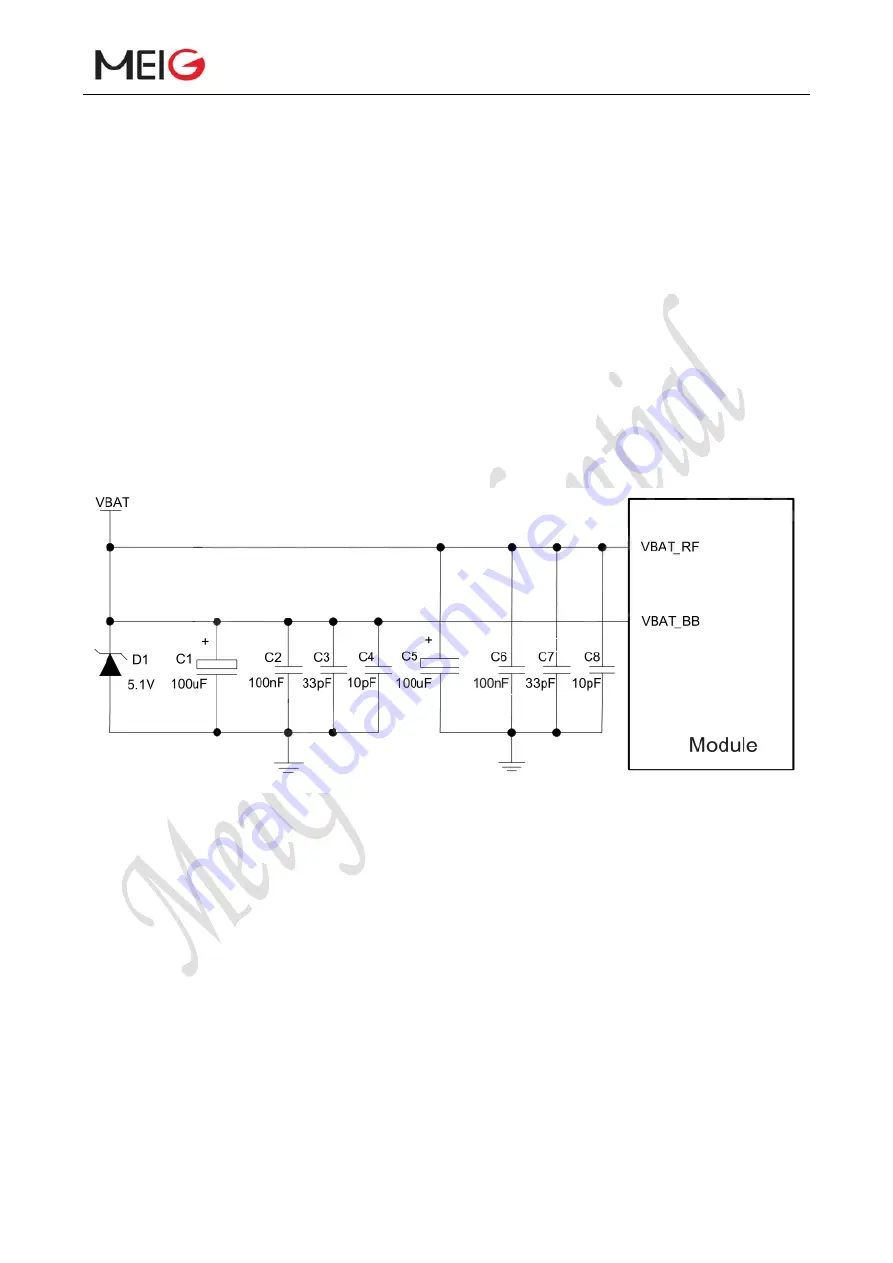

Figure 4 Power requirements for burst transmission

In order to reduce voltage drop, a low ESR 100uF filter capacitor is needed. The multilayer

ceramic capacitor (MLCC) has the best ESR, suggestion to add three ceramic capacitors (100nF,

33pF, 10pF) to VBAT_BB and VBAT_RF pins, and the capacitors should be placed close to the

VBAT pin. When external power supply makes connection to module, VBAT_BB and VBAT_RF

need to apply star line. VBAT_BB line width should not be less than 1 mm, and VBATRF line

width should not be less than 2 mm. In principle, the longer the VBAT line, the wider the line width.

In addition, in order to ensure the stability of the power supply, it is recommended to add a

Zener diode at the front end of the power supply with a power of 5.1V and a work and power of

0.5W or higher. The reference circuit is as follows:

Figure 5 Star structure of power supply

3.6.3 Reference design for power supply

The power design for the module is very important as the performance of the module largely

depends on the power supply. The power supply is capable of providing sufficient current up to 2A

at least. If the voltage drop between the input and output is not too high, it is recommended that you

use a LDO to supply power for the module. If there is a big voltage difference between the input

and the output, DCDC is preferred to be used as a power supply.

The following figure shows a reference design for +5V input power supply. The designed

output for the power supply is +3.3V (typical value 3.8V) and the maximum load current is 3A.