Page 10

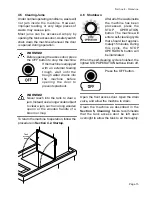

Figure 3-12: Drain connection

Machine

drain

Rubber boot

(supplied)

Clamp

(supplied)

2” OD drain line

(supplied by others)

S

ECTION

3 - I

NSTALLATION

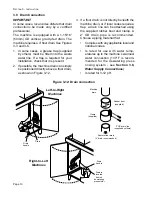

3.9 Drain Connection

IMPORTANT

In some cases, local codes dictate that drain

connections be made only by a certified

professional.

The machine is equipped with a 1-15/16”

(50mm) OD vertical, gravity-fed drain. The

machine requires a 4” floor drain. See Figures

3-3 and 3-6.

1. In some cases, a grease trap (supplied

by others) must be fitted into the waste

water line. If a trap is required for your

installation, check that it is present.

2. If possible, the machine drain can simply

be positioned directly above a floor drain,

as shown in Figure 3-12.

3. If a floor drain is not directly beneath the

machine drain, or if local codes require a

trap, a drain line can be attached using

the supplied rubber boot and clamp. A

2” OD drain pipe is recommended.

Choose a piping material that:

•

Complies with any applicable local and

national codes.

•

Is rated for use with water temp-

eratures up to the machine’s warmest

water connection (140°F is recom-

mended for the dewatering press

rinsing system - see

Section 3.8,

Water Supply Connections

)

•

Is rated for 3-12 pH.

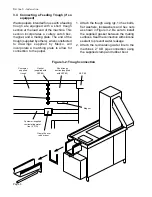

Route to floor drain

(4” drain recommended)

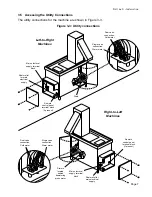

Drain

Left-to-Right

Machines

Right-to-Left

Machines

Drain

handle

Drain is

located

behind

dewatering

press motor

Drain

handle