Page 14

S

ECTION

4 - O

PERATION

4.3 Loading

Be sure to follow these guidelines when

loading waste into the machine.

The following waste can be processed:

•

Organic materials - Food residue (dining

areas), food waste (prep areas)

•

Inorganic materials - Small plastics and

polystyrenes (plastic utensils, Styrofoam

cups), cardboard, etc.

The following materials should NOT be fed

into the machine:

•

Metal

•

Glass

•

Porcelain and china

•

Large bones

•

Plastic bags

•

Oils and grease

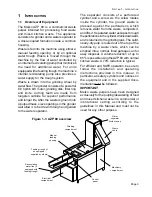

Waste can be loaded into the machine using

either the manual feeding opening or an

external recirculating feeding trough (if so

equipped).

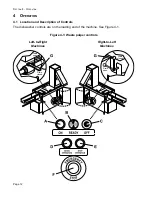

External feeding

trough (typical)

Manual feeding

opening

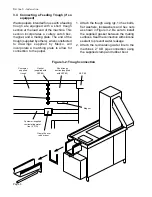

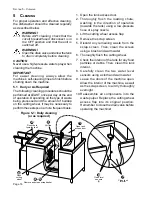

For the most efficient operation:

•

Load the waste steadily, instead of in large

batches or “piles.”

•

Waste should be mixed, instead of sorted,

when loading the machine.

•

Any containers (cups, etc.) loaded into the

machine should be opened and loaded

empty. Any remaining waste inside them

should be emptied into the machine first.

•

Any floating waste (Styrofoam, etc.) will

take longer to grind and process, reducing

the efficiency of the machine.

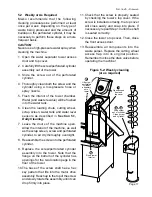

•

Some waste, particularly products that

have a high grease or oil content, may

produce a foaming effect in the tank. Other

wastes may accumulate on the cutting

wheel. Both of these conditions will reduce

the efficiency of the machine.

To reduce foaming and waste

accumulation on the cutting wheel:

-

Mix foaming wastes with other, more

absorbent wastes (cardboard plates,

etc.)

-

Add a foam-absorbing product (paper

or cardboard shreds, etc.) to the waste

mix.

Load the waste into the machine steadily,

instead of in large batches or “piles.”

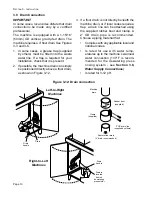

4.4 Idle Periods

During idle periods,

press the STOP

OPERATION button. The

machine will enter a 15-

minute self-cleaning

mode to flush debris

from the dewatering

press tower, and then

shut off the grinder,

separator and

recirculating pump.

To return the machine to operation, follow the

procedure in

Section 4.2,

Startup.