Page 5

3.2 Requirements Before Installation

Before the installer can uncrate and move the

appliance to the installation location, the fol-

lowing conditions MUST be met:

•

INSTALLATION AREA REQUIREMENTS

-

The area MUST be frost-free. Freez-

ing temperatures (32°F/0°C or lower)

inhibit proper operation and can dam-

age internal components.

-

The area MUST have a firm floor sur-

face. It is possible to compensate for

uneven flooring by adjusting the feet.

•

UTILTITY CONNECTION REQUIREMENTS

-

Connections must be present and

ready for hookup to the appliance. All

utility supplies must comply with the

electrical information labels, on the

data plate, and with all applicable lo-

cal and national codes.

-

Electrical leads and the water supply

lines (supplied by the customer) must

be present. The water supplies must

be of the pressure and temperature

specified on the data plate.

-

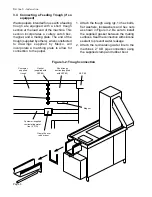

For units equipped with an optional

trough feeding system, the trough

should be present, and must match the

requirements of the machine as per all

specification sheets and supplied

drawings.

-

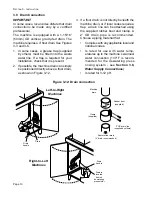

For units using a deodorizing system,

an appropriate dispenser or container

should be installed and ready for con-

nection to the appliance.

•

GENERAL REQUIREMENTS

Authorized personnel should be available

to perform the actual utility connections.

3.3 Uncrating, Positioning and Leveling

1. Remove all shipping and packaging ma-

terial from the appliance, including sup-

ports and wrappings. Leave the shipping

skid in place at this time to allow for easier

movement to the installation location.

2. Check for shipping damage as described

in

Section 2,

Transport and Shipping.

If damage is present, call Meiko Customer

Service at

1-800-868-3840

, providing full

details on the customer, serial number and

S

ECTION

3 - I

NSTALLATION

extent of damage present. Meiko will file

a freight claim based on this information.

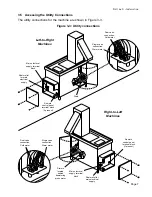

3. Move the appliance to the installation area

and remove the skid. Meiko recommends

using a pallet truck to lift the entire pallet

and avoid damage to the machine. Use

caution to avoid damaging the appliance

or any of its components.

CAUTION

If the pallet is removed, the frame of the

machine can be damaged by improper

lifting. Always use wooden members to

properly distribute the machine’s weight

and avoid damage. Note that motors or

other components may extend below the

frame; use caution to avoid damaging

these components.

CAUTION

Do not attempt to slide the machine on its

feet. This may damage the feet or bend

the legs of the machine. Move the

machine to the installation location by

lifting it, using a palette truck with wooden

members to distribute the weight.

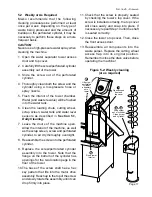

5. Using a spirit level, check that the

appliance is level in both directions (front-

to-back AND side-to-side). If necessary,

level the appliance by accessing the bolts

above each foot and adjusting them using

a 17mm wrench. It is necessary to lift the

machine to remove the pressure from the

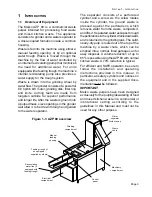

foot before adjustment. Refer to Figure 3-1.

CAUTION

The waste pulper MUST be level for

proper operation.

Figure 3-1:

Foot

adjustment

17mm

Open access doors or

remove side panels to

access adjustment bolts

Lift machine to remove

pressure before

adjusting foot

Adjustment

bolt

17mm

wrench