DMW-22-TDL SERVICE MANUAL

Confidential and proprietary information of Meister Cook, LLC. Not to be reproduced or used in any manner other than

with the express written permission of Meister Cook, LLC.

13

|

P a g e

o

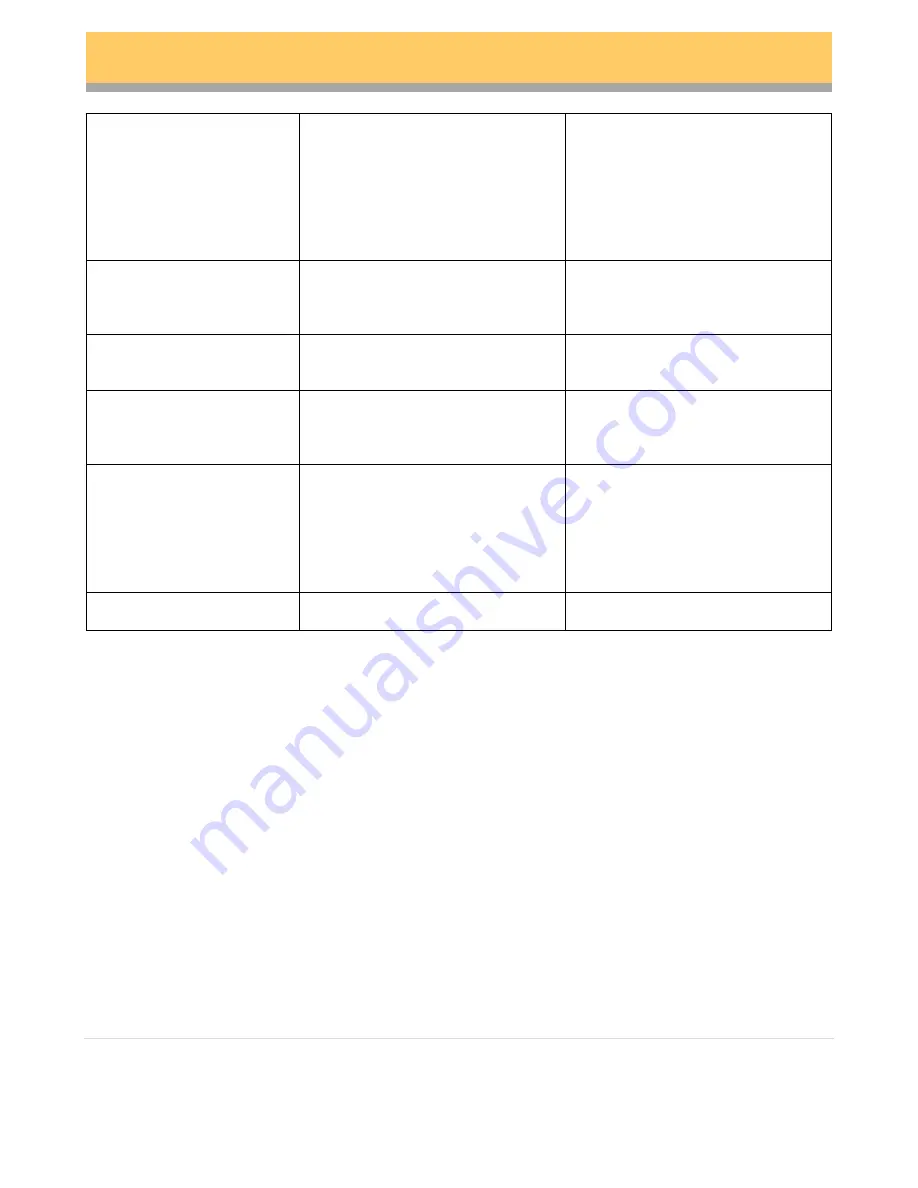

Low resistance

-

Check for crossed thermocouple

connections

-

Check for damage to wire harnesses

-

Check for short circuits

-

Test for proper heater current draw

from power supply

-

Test with new UI board

“FLT! 1111”

-

Verify this occurs at times other than

power down

-

Check if system works if plugged into

another outlet or circuit

-

Check for damage to wiring harnesses

-

Test with new power supply

-

Test with new UI Board

Loud noise continuous coming

from system

-

Verify noise can be easily heard from

5-6 feet away from the system

-

Check for foreign objects or debris in

system

-

Test with new blower

Garbled text on display

-

Cycle power to system

-

Restore system defaults

-

Check connections to UI Board

-

Check programming port on UI Board

for bent pins

-

Test with new UI Board

Smoke generated by system

-

Have operator shut off system

immediately, if they have not already

done so

-

After shutting off the system, have

operator unplug system from outlet

-

Verify no obvious foreign objects are

present

-

Check for presence of foreign objects

-

Check for damage to wire harnesses

-

Check for short circuits

-

Test for proper heater current draw

from power supply

-

Test with new UI Board

Popping noise coming from

system

-

No resolution over the phone

-

Check for damage to wire harnesses

-

Check for short circuits

When assisting over the phone, it is essential to gather as much information as possible. Such data

includes, but is not limited to:

Site information (store number, location phone number, contact(s))

Number of systems, along with serial number(s) and location(s) within the store

Serial number of system under complaint

Reported fault symptom(s)

Frequency of fault symptom(s)

Make sure the caller is in front of the system under complaint. It is essential for them to be able to

exactly describe the failure symptom(s). When in doubt, err on the side of asking too many

questions.

If the caller is reporting problems with temperature and/or quality of

food products

being served

from the DMW, it is essential to re-direct them to the system to determine if there is an actual fault

with the DMW. Food product temperature and/or quality can potentially be linked to several factors

unrelated to the DMW.