262 of 271

Critical Measurements

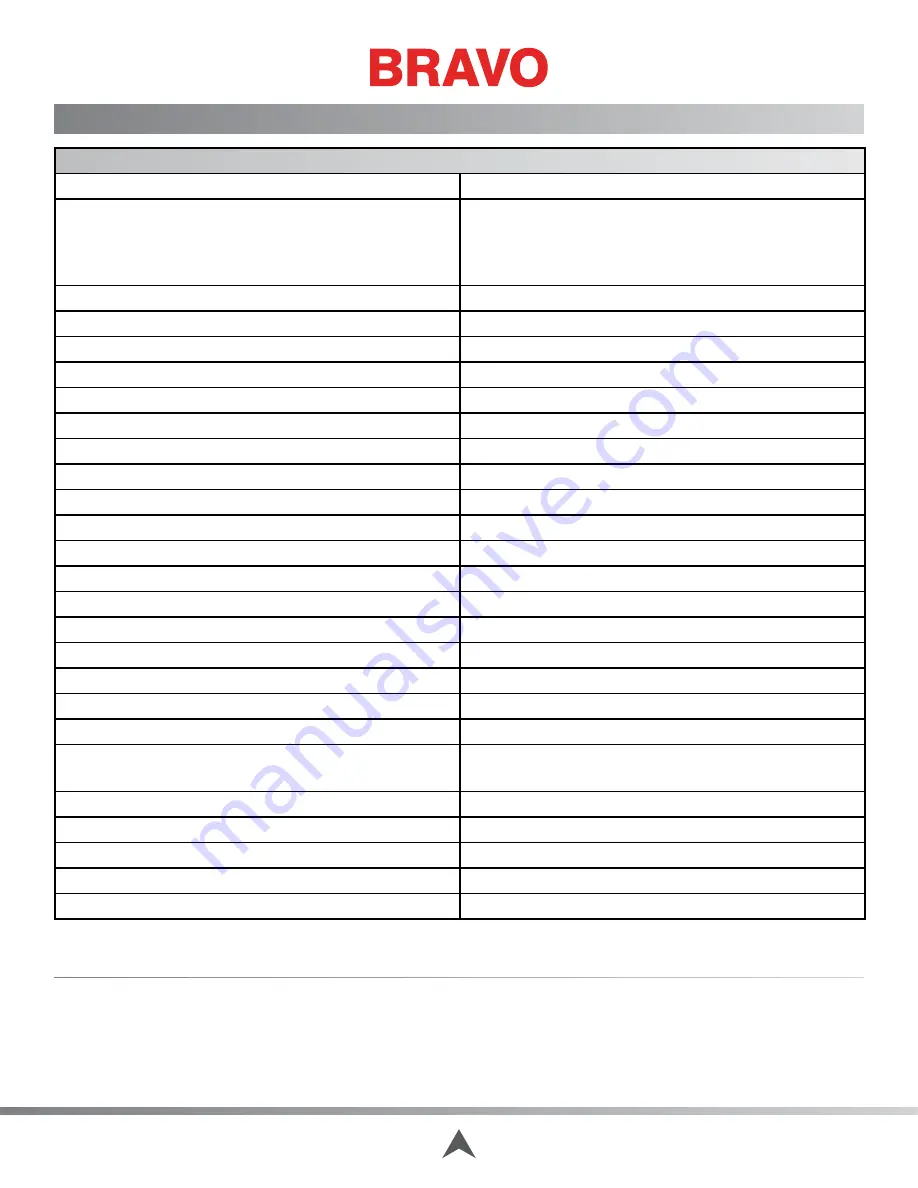

Contents & Critical Mechanical Settings and Assemblies

Introduction

Set the angle of your PCB before you set the

Z-timing.

Z-TIMING: Bottom Center and Head Timing

179.5-180.5 Z-degrees - Bottom Dead Center

Hook Timing: 201.5° ± 0.5°

.001” [0.028mm] Z-Axis Rise: 182 ° - 183 °

Needle Depths

1/4-1/2 of through portion of needle eye

Hook Timing

201.5° ± 0.5°

Needle Drive Stud to Reciprocator Fit

0.006” [0.15mm] max.

Upper Arm to Lower Bed Alignment

True position:.010” (±0.004”)

Needle Case Calibration

True position:.010” (±0.004”)

Needle to Hook Gap

0.004- 0.012” [0.1- 0.3 mm] (reference)

Hook to Retaining Finger Gap

0.018” -.022” [0.46 mm - 0.56 mm] minimum

Take-up Lever Stroke

56-58 mm

Take-Up Lever Fit to Shaft

Free Rotation

Take-Up Lever End Play

0.030-0.040” [0.75-1.15mm]

Cam Follower Preload

4.5-5.0 in-lbs.

Pull Force on Take-Up Lever

1.4-1.5 lbs

Color Change Lead Screw

0.025” [0.64mm] straightness

Color Change Housing Location

Bobbin Tension

22 to 25grms/force

Presser Foot Adjustment @ BDC

0.1- 0.6 mm

Thread Feed FWD 200

88-90 mm

Needles

DBxK5 75/11

Needle Orientation

5° to the right recommended

range of 0°-20° to the right is acceptable

Z-Belt Tension

68-72 Hz [6.8±0.3 lbs.]

X-Cable Tension

145 ± 5 Hz [10.5 ± 0.5 lbs.]

Y-Axis Timing Belt Tension

45-50 Hz [8.1 ± 0.3 lbs.]

Maximum Front to Back Needle Position Variance

.006” [0.15mm]

Proper Lubrication of Moving Parts

Introduction

The critical measurements in these instructions were extracted from Engineering documents that estab-

lish the official criteria for adjustments and settings on the embroidery machine. Deviation from these

standards is not authorized unless a deviation order signed by the manufacturer is received. Failure to

Table of Contents