76 of 271

Needle Depth

The needle depth should be set after any of the following:

• replacement of any of the needle bars or needlecase assembly four-packs

• disassembly of the needlecase assembly

• when diagnostic tests determine resetting of needle depth is necessary

To set the needle depth, the software must be launched and the machine must be turned on. Refer to

the following procedures to set the needle depth.

Setting the Needle Depth by Eye

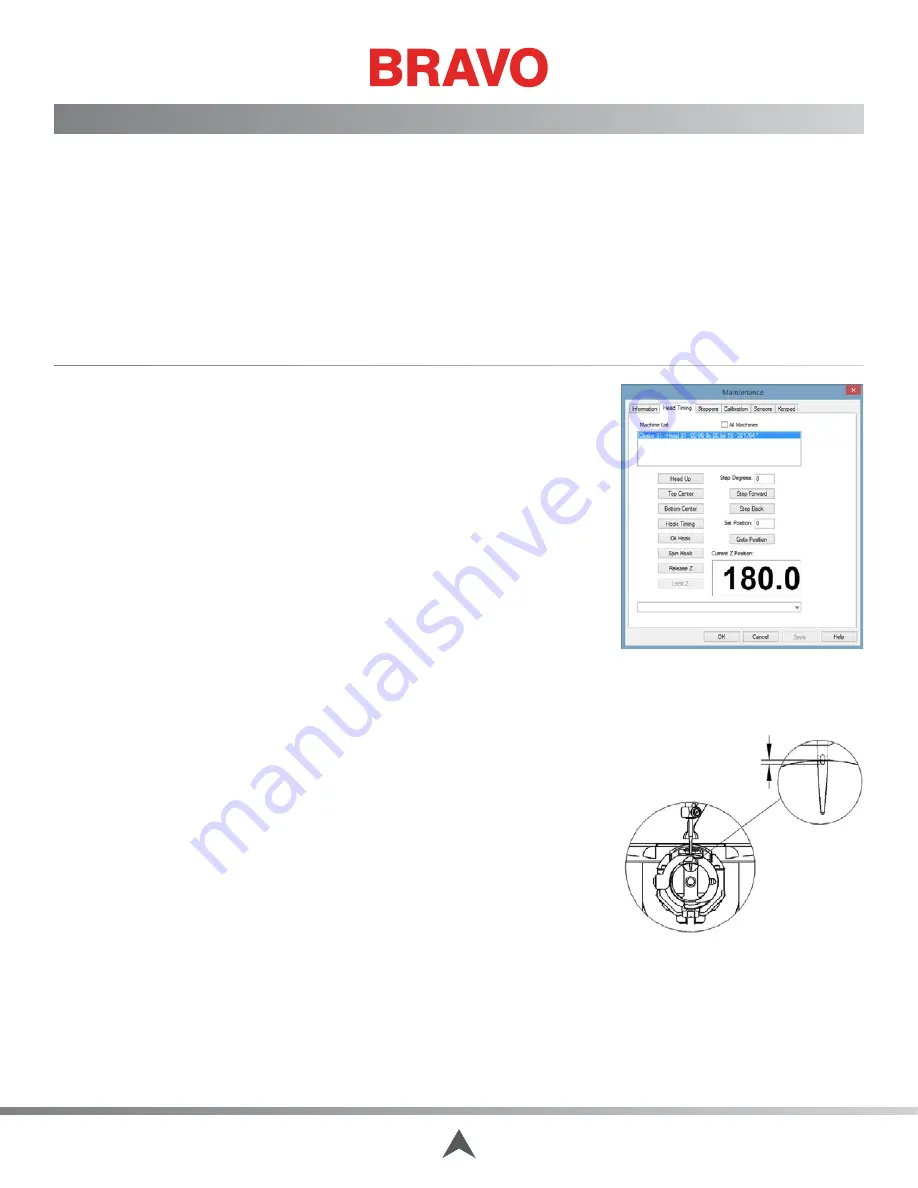

1. Click the Maintenance menu on the Bravo OS main menu screen,

and then click the Head Timing tab to open up the Head Timing

menu.

2. Remove the bobbin case and bobbin (if installed) and then click the

Head Up button and then color change left to Needle 1.

3. Click on the Bottom Center button.

4. Look directly into the hook assembly and check the location of

the needle’s eye compared to the figure above. 1/4 - 1/2 of the

through portion (the portion that you can see through) of the

needle eye should be visible in the hook assembly. If the needle’s

eye is in the acceptable range, skip the next few steps and go to

Step 7. If the needle’s eye is not in the acceptable range, contin-

ue this procedure with the next step.

5. Loosen the set screw on the needle bar drive stud and move the

needle bar up or down until needle depth is correct. (1/4 - 1/2

of the needle eye through portion should be visible) Repeat step

4 above and repeat this step again if the needle depth is not

correct.

6. Click the Head Up button and then the Bottom Center button

and check that the needle is at the proper needle depth position.

If it is not, go to step 5 above.

7. Click on Head Up. Color change to the next color.

8. Repeat steps 3 through 7 until needle depth is set on all 16 needles.

9. Reinstall the bobbin and bobbin case.

10. Run the following test designs on the machine:

• AMTBTESTXXX.EXP (Thread Break Test)

• AMRTESTXXX.EXP (Looping Test)

Figure 1 - Head Timing Menu

Figure 2 - Needle Depth

Table of Contents