152 of 271

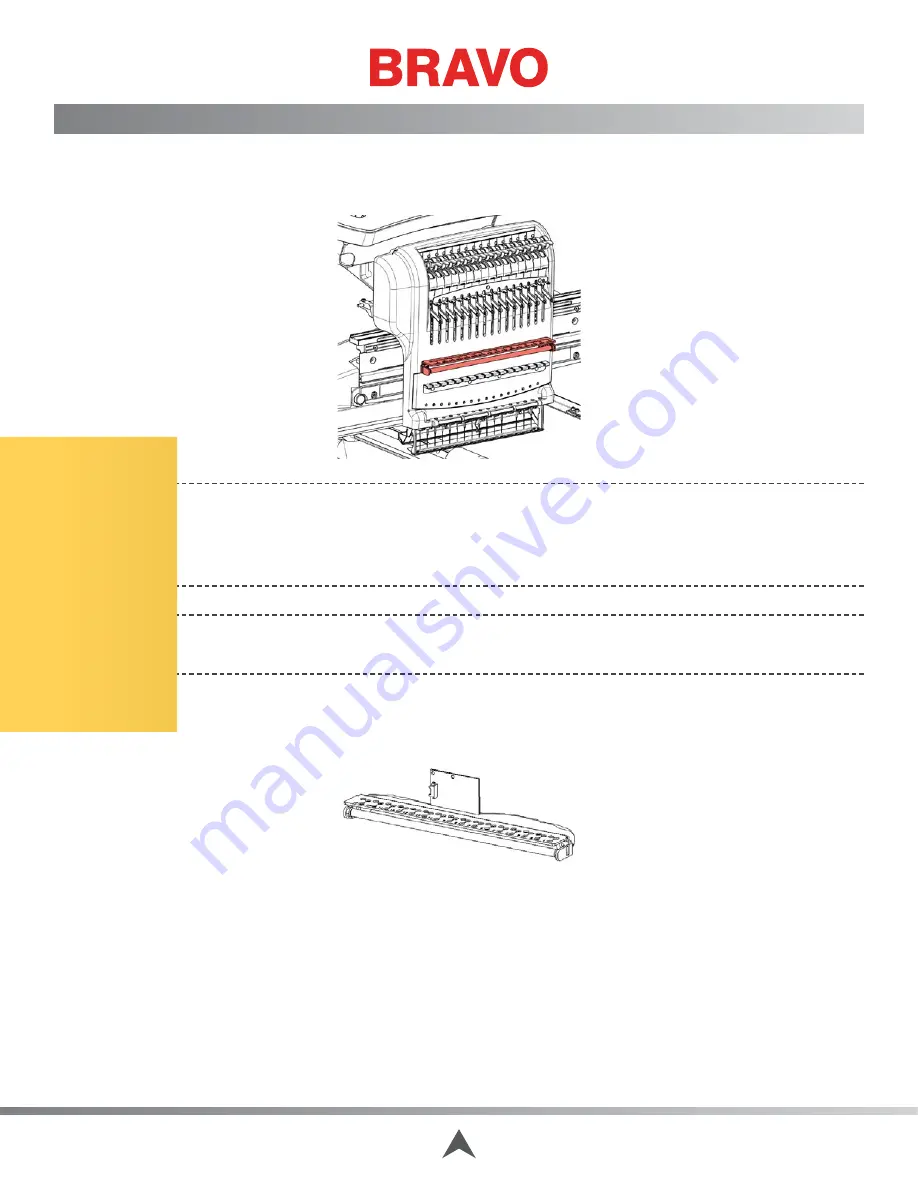

Thread Sensor Assembly Replacement

The thread sensor assembly has to be replaced when diagnostic tests indicate it has failed. Symptoms

such as inconsistent thread feed, inconsistent thread tension, and an increase in tension can be related

errors during embroidery operations.

CAUTION!!

Handle the thread sensor assembly carefully. The wiring is extremely fragile to han-

dling. Although this assembly is resistant to electrical static discharge (ESD) damage, use normal

precautions when handling electrical components. Parts that are damaged due to mishandling

are not covered under the machine warranty.

CAUTION!!

DO NOT allow the PCB or bracket to hang by the wires. Support the weight of the

PCB during installation or removal.

Replacement Parts Needed:

• Thread Sensor Assembly

If the assembly is loose, you may want to re-assemble with tape, seating each bracket boss into the

thread guide holes.

1. Remove the needlecase access cover.

2. Remove any thread from the needlecase.

3. Remove the needlecase cover.

4. Remove the two M3 nuts mounting the thread sensor PCB to the needlecase and remove the PCB.

Table of Contents