14. If replacing the X drive belt, refer to the belt replacement and adjustment

procedure at this time, otherwise proceed directly to the X drive belt tensioning

procedure for instructions tightening the belt to the proper tension.

X Drive Belt

This belt is directly driven by the X motor shaft pulley and moves the X carriage left

and right along the rail in the base of the X beam.

Replacement

NOTE:

This procedure requires a specific Melco force gauge (p/n 995585-01), for

proper adjustment.

Refer to the following procedure to replace the X drive belt:

1. Turn OFF the power switch to the EMT 1 and remove the power cord from the

power source electrical outlet and the rear of the machine.

2. Remove the X beam cover by first removing the six button head screws on the

top, then lifting the cover off the entire length of the X beam.

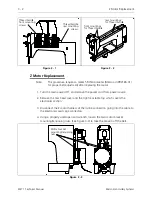

3. Refer to Figure 2-14 and loosen the drive belt tensioning screw, then the two

tensioner block mounting screws to loosen the drive belt.

4. The existing X drive belt is clamped and held to the X carriage plate by two flat

head socket screws, a clamp, and a spacer. The screws go through holes in the

belt as well. Remove the two flat head socket screws and associated clamp and

spacer to free the belt at this area (see Figure 2-14).

5. Slide the old belt out of the two pulleys at either end and position the new belt

into place where the old one was.

6. Bring the ends of the new belt together above the two holes in the X carriage

plate.

7. Position the X belt clamp above, and the spacer below the belt ends,

sandwiching the belt between them.

8. Insert the two flat head socket screws through the clamp, the holes in the belt

ends, the spacer, and into the holes in the X carriage plate.

9. Refer to the following belt tensioning procedure for adjusting the X drive belt

tension.

X Drive Belt

2 - 19

110344-01, Rev B

2. Service Maintenance (except embroidery head )