1. Refer to the procedure for removing the left rear table top (with optional bobbin

winder assembly) and remove the table top.

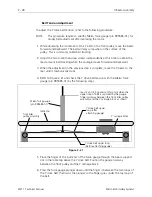

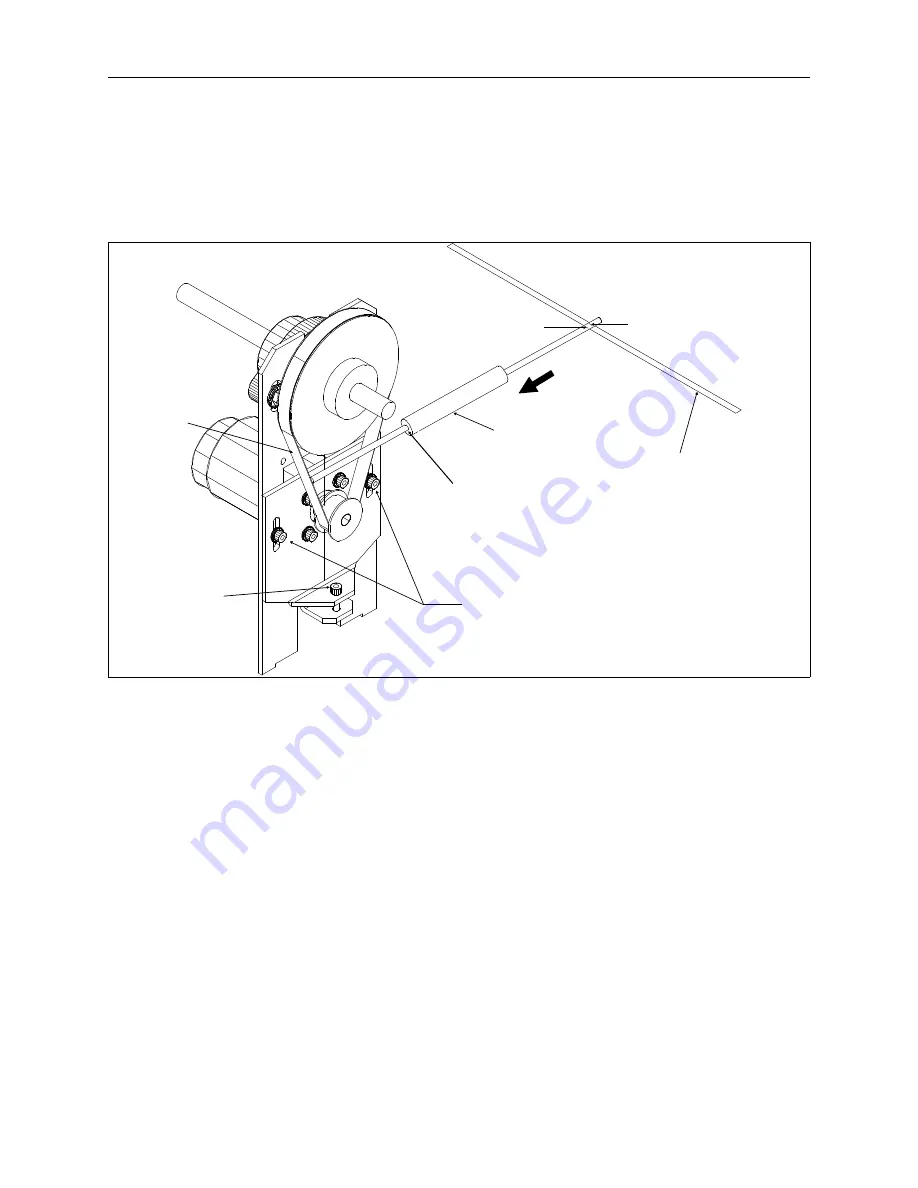

2. Refer to Figure 2-18 and check the Y motor belt tension using the Melco force

gauge (p/n 995585-01) and the steps that follow:

3. Orient the Melco force gauge (p/n 995585-01) diagonally between the Y motor

belt and the top edge of power distribution section of the peripheral as shown

in Figure 2-18. The ’push end’ of the gauge should be toward the belt.

4. Place the finger of the ’push end’ of the gauge against the inside (toothed

surface) of the rear loop of the belt and mid-way between the pulleys centers.

The gauge plunger should be located just under the large Y shaft pulley when

positioned correctly. The other end of the force gauge plunger will be resting

against the top edge of front wall of the power distribution section.

5. Place a pencil mark on the plunger at the location where the inside surface of the

power distribution section wall touches the plunger.

6. Measure 0.2 inch toward the end of the plunger from the mark made in the

previous step and place another pencil mark on the plunger at that location.

top edge of power

distribution section

of the peripheral

belt

tensioning

socket head

cap screw

make first pencil mark

here at inside surface

of wall edge

make second pencil

mark here (0.2" from

first pencil mark)

read 10 +/- 2.0 pounds at this

point when the gauge is

positioned at the second mark

on the other end of the plunger.

Melco force gauge

(p/n 995585-01)

Y motor belt

(rear loop)

motor bracket securing

socket head cap screws

Figure 2 - 18

2 - 24

X Beam Assembly

EMT 1 Technical Manual

Melco Embroidery Systems