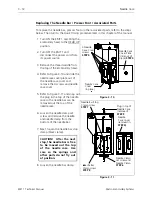

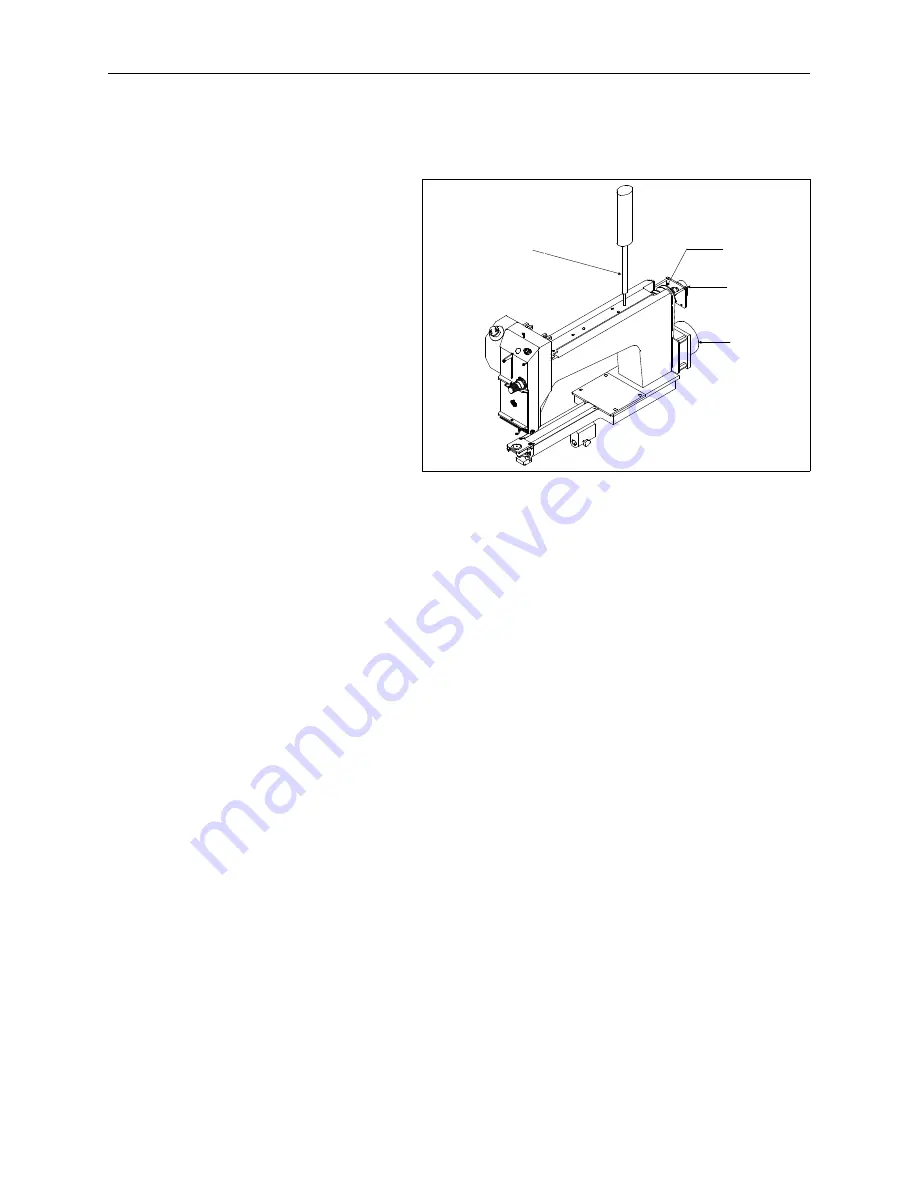

5. Position the Melco head up alignment pin tool (995338-01) or the Melco 10

needle head up fixture (p/n 995673-01) into the head up alignment hole in the

top of the head as

shown in Figure 3-6.

6. Slowly rotate the head at

the Z drive pulley until

the head up tool pin

inserts into the hole in

the head up alignment

collar on the Z shaft.

This is the "mechanical"

head up position.

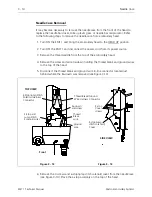

7. Now loosen the two

encoder shaft coupler

cap head screws (B) at

the embroidery head Z

shaft (see Figure 3-5)

and slowly rotate the

coupling in either direction until the LED glows.

8. When the LED is glowing, tighten one of the encoder coupler cap head screws to

the embroidery head Z shaft.

9. Remove the head up tool and rotate the Z shaft until you can access the second

cap head screw on the encoder coupling to Z shaft.

10. Remove the screw and apply a small amount of Loctite 222 hardware adhesive

(or equivalent) and reinstall and tighten it.

11. Return to the first encoder coupler cap head screw, remove the screw and apply

a small amount of Loctite 222 hardware adhesive (or equivalent), then reinstall

and tighten it.

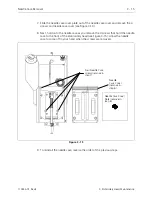

12. Turn the embroidery peripheral OFF and attach the network cable (or install the

boot disk).

13. Turn the embroidery peripheral ON again and allow its program to download.

14. Go to the head timing menu and check that when the head is brought to head

up, that the green ZINDEX LED on the front of the machine or the innermost

LED on the CPU glows within plus or minus 1.5 degrees of head rotation.

15. Reinstall thread saddle and any other covers removed during this procedure.

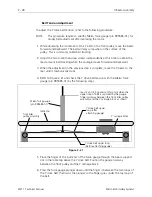

Z drive

pulley

Z Encoder

Z Motor

head up

alignment

pin tool

Figure 3 - 6

3 - 8

Z Shaft Encoder

EMT 1 Technical Manual

Melco Embroidery Systems